Huntsville Councilman Mark Russell released from hospital after heart attack

Huntsville City District 2 Councilman Mark Russell had a heart attack Friday night while refereeing the Madison Academy football game. Russell collapsed on the field and emergency crews administered CPR at the scene before the Councilman was transferred to Huntsville Hospital. There, doctors were able to stent a blocked artery successfully. According to Kelly Cooper Schrimsher, a spokeswoman for the City of Huntsville and Mayor Tommy Battle, Russell is now in good spirits and says he feels better than he has in a long while. On Monday, he was released from the hospital. “April and I are grateful on so many levels, and we thank everyone for the outpouring of concern and support we’ve received through this ordeal,” Russell said in a statement ahead of his release. Russell has served on the Huntsville City Council since 2002.

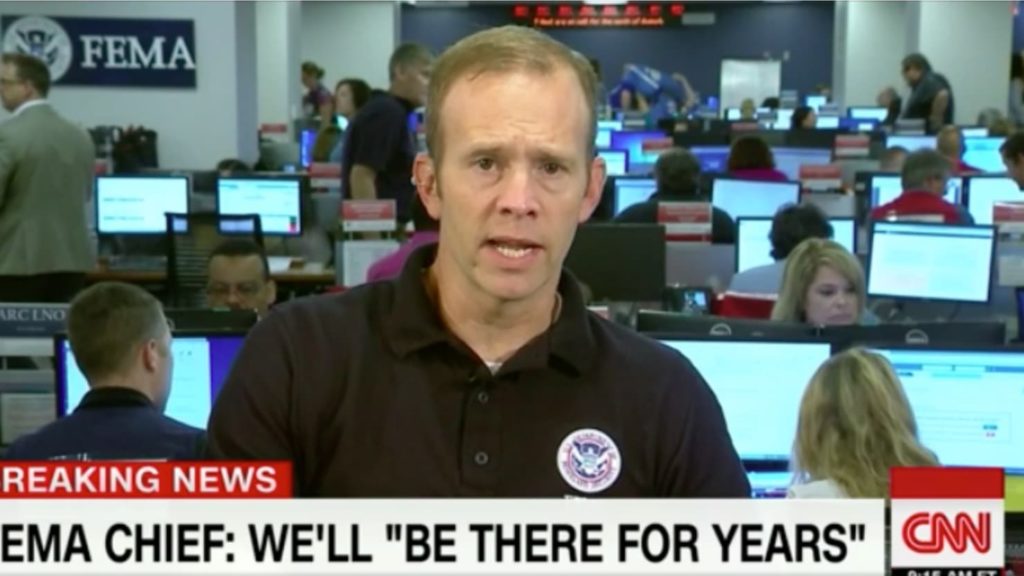

Former Alabama leader, FEMA Director Brock Long faces first first big test

Brock Long, the Director of the Federal Emergency Management Agency (FEMA), is getting ready to face one of the toughest challenges of his career — coordinating the federal response to the damage done by Hurricane Harvey in Houston, Texas. While he’s only been on the job for two months, Long will be relying on years of experience in working with natural disasters in the weeks, months and years of Hurricane Harvey clean-up that lies ahead. From 2008 to 2011 Long served was at the helm of the Alabama Emergency Management Agency (AEMA), where he worked on the Yellowhammer State’s response to the Deepwater Horizon oil spill and numerous other natural disasters. As Director, he served as the State Coordinating Officer for 14 disasters, including eight presidentially-declared events. Prior to that he was a FEMA Regional Hurricane Program Manager from 2001 to 2006. Long’s already relying on his experience as the storm continues to do damage to the Lonestar State. On Monday, he asked for all Americans to help in what will be a lengthy recovery from the historic flooding caused by Hurricane Harvey. “Helping Texas overcome this disaster is going to be far greater than FEMA coordinating the mission of the entire federal government,” Long said at as news conference in Washington. “We need citizens to be involved. This is a landmark event. We have not seen an event like this. You could not draw this forecast up. You could not dream this forecast up.” “This is a whole community effort,” he added. The extent of the damage remains unknown, and the rainfall is not expected to let up for several days. Long urges individuals and organizations to check the website nvoad.org or call 1-800-621-FEMA to find out how to help.

Alabama sleeping bag maker among American-made survivors

Entire industries, from textiles to toys, have become almost extinct in the U.S. as manufacturers moved abroad in search of lower costs or got swept away by a wave of imports. Some products aren’t Made in America at all anymore. Others still are – but by just a handful of small businesses, or maybe only one. They’re mostly surviving by the skin of their teeth in a world where shoppers care more about price than country of origin. Their stories show the challenge of producing at home – as President Donald Trump is pushing for – and also that it’s not impossible. Exxel Outdoors LLC Sleeping bag maker Exxel had about a half-dozen rivals in the mid-1990s, according to Chief Executive Officer Harry Kazazian. Most had moved overseas by 2000 when he and co-founder Armen Kouleyan bought the Haleyville, Alabama, factory. The company is now the largest sleeping bag manufacturer in the nation. “We’re proud that we’re the last man standing,” Kazazian says. “We stuck with it, and it paid off.” Since 2000, the factory’s employees have more than doubled to 95; they produce about 2 million sleeping bags a year. Import competition remains cutthroat in the below-$30 range for the high-volume, mass-retail business. Exxel makes its own brands, Disney– and Marvel-licensed ones, and retailers’ private labels. Wal-Mart Stores is its biggest buyer. Exxel added outdoor-gear brands such as Wenzel and Kelty with an acquisition in 2015, diversifying its offerings to include $689.95 Sierra Designs tents and $299.95 Slumberjack hunting backpacks. While many of Exxel’s products are produced in China, it makes more sleeping bags in America than overseas. They account for more than a third of annual sales, which exceed $100 million. In 2008, when the weakening dollar and rising foreign wages tilted the advantage toward U.S. manufacturing, Kazazian, 55, brought some production back from China. The factory has maximized automation, though workers do quality control and other tasks such as operating quilting machines. Ten-hour, four-day workweeks limit energy costs. The fiberfill, threads and packaging cartons are all bought from U.S. suppliers. Still, some things just aren’t done at home. When retailer demand for “Star Wars” sleeping bags surged late in the holiday season last year, Exxel tapped contract factories overseas to supplement its American production. Shells and carry-cases for the bags are imported as the necessary low-cost, polyester taffeta isn’t available here. As Kazazian says, “a percentage of something here is better than 100 percent of zero.” Dubuque Clamp Works Dubuque, Iowa, had a thriving industrial economy until the 1980s. Now, not so much. Keith Clark is still there, making woodworking clamps, as he’s done for four decades. The company he co-owns with his wife, Edna, has annual sales of $500,000, with customers from Germany to South Korea. Clark, 72, turns away new orders, partly because so much of the supply chain he relies on has moved abroad. Rivets and springs can take weeks to arrive. He often ends up making his own parts. “That’s the reason it’s going to be hard for manufacturing to come back,” Clark says. “You need all these sundry businesses to be here.” So Dubuque Clamp stays small by design, employing three people plus part-timers. It does some custom molding, but 90 percent of its output is specialized clamps for holding wood in place. The clamps are manufactured on about 50 dedicated machines and used to make everything from cabinets to countertops and guitars. “If a clamp isn’t perfect, it doesn’t go out. We just throw it away,” Clark says. “If anybody breaks a part, we just replace it, no questions asked.” That means higher price tags than mass-produced imports. On Amazon.com, his 6-inch handscrew clamp costs $24 – not the cheapest option, though not the most expensive either. Clark doesn’t see the need for his own website or any marketing; customer testimonials bring in plenty of sales. But “nobody in their right minds probably wants to do this anymore,” he says about the industry. “It’s too demanding.” One of his last U.S.-based rivals, which made Pony and Jorgensen clamps, was sold to a China-based buyer after shutting its business operations last year. Clark likens himself to “the last Mohican. Boy, that’s probably how they felt.” American Mug & Stein Co. “Everything is made the old way,” says owner Clyde McClellan, 68. “It’s not high-volume or mechanized.” Fifteen employees – down from 35 in the company’s heyday – cast ceramic mugs by hand into molds, then glaze and fire them in kilns. There’s rich clay to be found near American Mug’s base in East Liverpool, Ohio – known as the nation’s pottery capital in the 19th century. Foreign competition led to a steady erosion, and the last recession dealt another blow. American Mug and another firm are the only holdouts in town. McClellan, a 44-year veteran of the industry, bought the company in 2009. Then, in 2011, along came Starbucks Corp. The coffee chain was running a campaign to encourage American products, which led it to McClellan. “Starbucks came out of nowhere,” and suddenly there was hope, and more orders than ever, he recalls. The publicity around that deal has brought in almost all his new clients in recent years, McClellan says. “We’ve had to reinvent ourselves. Instead of having customers adapt to us, there are deadlines now,” and he’s more selective about accepting orders. Oktoberfest is the busiest time for beer steins, while coffee mugs are cranked out at maximum capacity all year. Starbucks still buys about 35 percent of them. The pottery’s special commemorative mugs have, through contractors, made their way to patrons such as the Smithsonian’s Hirshhorn Museum and the U.S. Navy. McClellan says he needs two more workers, but the region’s drug-abuse problem has made the search harder. “You need good hand-eye coordination” to avoid breaking things or wasting materials. His staff can earn as much as $13 an hour, though it’s in high temperatures, and “people don’t like to get their hands dirty” with clay these days. For every mug McClellan produces at a wholesale cost of $3.50, chain-store suppliers can get one from China at 85 cents to $1, decorate

Kay Ivey announces inaugural disability job fair

According to a 2015 American Community Survey, 14.9 percent of Alabamians are living with a disability, 21,283 individuals are unemployed. Employment is one way to support and improve their quality of their life while adding to the diversity of the state’s workforce. Which is why Governor Kay Ivey on Monday announced the Governor’s Inaugural Disability Job Fair. It will take place during National Disability Employment Awareness Month — an month-long, nationwide celebration of the contributions of workers with disabilities and an opportunity to educate the public about the value of a workforce inclusive of their skills and talents — in October. Ivey made the announcement at United Ability, formerly United Cerebral Palsy of Greater Birmingham, following a tour of their facility which provides a wide range of programs to assist children and adults living with disabilities. “Since becoming Governor, I have made it my priority to increase employment opportunities for all Alabamians. The inaugural Governor’s Disability Job Fair is just the start of what I hope will continue bridging the gap between employers and individuals with disabilities,” Ivey said. “When our state agencies work together, share resources and partner with the private sector to help connect businesses looking to hire with individuals actively seeking employment, Alabamians can rest assured we are doing our best to improve their quality of life.” The first Governor’s Disability Job Fair will be held on October 30th from 10 a.m. to 2 p.m. at the Bill Harris Arena in Birmingham. The job fair is being made possible by a joint partnership between United Ability and several state agencies including the Department of Labor, Department of Mental Health, Department of Rehabilitation Services and the Governor’s Office on Disability. “We brought dozens of employers together last year for a Disability Employment Summit, and today’s announcement of the Governor’s Disability Job Fair is a direct result of that effort,” Secretary of the Alabama Department of Labor Fitzgerald Washington explained. “Employers are ready and willing to offer opportunities to Alabamians living with a disability, and there are thousands of Alabamians ready and willing to do the work. We’re here to help bring them together.” “The Governor’s Office on Disability is proud to be one of the partners supporting the first Governor’s Disability Job Fair. The unemployment rate of people with disabilities continues to remain unacceptably high,” Executive Director of the Governor’s Office on Disability Graham Sisson added. “This event will continue the state’s combined efforts to increase employment opportunities for those with significant disabilities. I applaud Governor Ivey’s leadership in this area.” Employers and jobseekers can register online for the job fair at labor.alabama.gov/jobfair by selecting the “Governor’s Disability Job Fair” tab.

Safran to open aerospace manufacturing facility at Mobile Aeroplex

French aerospace giant Safran plans to open a manufacturing operation at Mobile Aeroplex — home to the Airbus A320 Family assembly line — and hire 20 employees over the next three years, according to the Mobile Area Chamber of Commerce. The company will produce and install aircraft engine nacelles at this facility. Paris-based Safran is one of the world’s two leading integrators of aircraft engine nacelle systems, which house an aircraft engine and its related components. “Safran is excited to be part of the growing aerospace community in Mobile,” said Peter Lengyel, president and CEO of Safran USA. “We are pleased to move forward with this investment in Mobile.” To house the facility, the Mobile Airport Authority is building out one of the existing bays at Mobile Aeroplex to 24,500 square feet, according to the Chamber. In addition, the company is investing approximately $1 million in equipment, with an opening planned for November. Safran is the 19th company to locate at Mobile Aeroplex at Brookley since Airbus launched production in Alabama, said Mayor Sandy Stimpson. The company joins a growing list of aerospace companies with a strong presence in Mobile, with examples including VT MAE, Continental Motors and MAAS Aviation. “We are pleased and proud to welcome Safran to the family of aerospace companies choosing to invest in Mobile,” Stimpson said. “Mobile is open for business, and our future has never been brighter.” Air Show connection The announcement comes two months after a high-level delegation from Mobile met with Safran USA’s executives at the Paris Air Show. “It’s exciting to see Team Mobile once again successfully recruit another world-class aviation and aerospace industry partner to our area,” Mobile County Commissioner Connie Hudson said. The Mobile Area Chamber said discussions to locate the facility in Mobile were finalized at a meeting in Paris that included Safran USA decision-makers, Stimpson, Hudson and Mobile Airport Authority’s Mark McVay. “Safran is yet another worldwide company in the aerospace industry to call Mobile home. Their manufacturing presence within our aerospace hub will continue to pay dividends in our future recruitment efforts in the industry,” said David Rodgers, a senior project manager who led the recruitment efforts for the Chamber. Aerospace expansion Safran’s announcement comes amid a growth spurt for the Alabama aerospace sector. In 2016, aerospace firms announced projects involving $260 million in new capital investment and 2,000 jobs, according to Alabama Department of Commerce data. This year has brought a string of high-profile aerospace announcements from companies such as Blue Origin, Leonardo and Aerojet Rocketdyne. “Alabama is involved in virtually every aspect of the aerospace industry, from R&D activities and raw material production to aircraft assembly and component fabrication,” said Greg Canfield, secretary of the Alabama Department of Commerce. “This puts the state in a prime position for sustained growth in a dynamic industry.” This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

Bradley Byrne: Back to school leadership tips

Earlier this year, I was asked to compile my thoughts on leadership and what it means to be an effective leader. With students back in school, high school football season underway, and college football right around the corner, I wanted to share some highlights from my leadership journey with students, athletes, and others. Throughout my professional and personal life experiences, I’ve found these three simple tips, and I think they can apply to each and every one of us. (1) Leaders Trust Their Team: A leader is only as good as the people around them. But, just having a team is not enough. You have to be able to trust them to do their job. There is nothing wrong with asking for help and surrounding yourself with talented people who can help you achieve your goals. I honestly believe I have the most talented staff on Capitol Hill and an equally talented team working for me back in Alabama. I depend on my staff all the time, whether it is briefing me on a legislative priority or arranging my complicated schedule. I could never achieve all of my goals in Congress without my first-rate team. (2) Leaders Listen: Far too often we spend all of our time talking when we should actually be listening. Stopping to listen to the ideas of others allows you to be better at whatever it is you are doing. This is why I value holding town hall meetings. I have held over 85 in-person town hall meetings since being elected to Congress, and that number goes over 100 if you include telephone and online town halls. I don’t see these meetings as an opportunity for me to talk. Instead, they are really a chance for me to listen to the people I represent. To be clear, listening does not mean you always have to agree with the other person or change your opinion. Sometimes I agree with what the individuals say and sometimes I disagree, but that is the value in listening. It is always helpful to hear different perspectives on any issues or topic before making a decision, giving you a wider range of understanding. (3) Leaders Never Give Up: July 13, 2010 was a difficult night for me. It was the night I lost the runoff in the Republican primary to be the next Governor of Alabama. It had been such a grueling campaign for my family and me, but, most importantly, I truly believed we could have made a really positive impact on our state. However, it was not to be. It would have been easy for me to let that moment define the rest of my career. I could have given up on public service altogether. Honestly, the thought crossed my mind. Then, in May of 2013, Congressman Jo Bonner announced he was resigning from the U.S. House of Representatives. I once again had the chance to serve the state and people that I love. The message here is to never let the fact that one door closes force you to give up on something you are passionate about. The question is never whether you will experience some level of setback or failure, because every leader will. The real question is how will you respond and overcome the setback. That is what will define you. It is my hope that these three simple tips will help our young people as they head back to school, but the tips can apply to any of us, regardless of where we are in life. We should never miss an opportunity to learn from our friends and neighbors. • • • Bradley Byrne is a member of U.S. Congress representing Alabama’s 1st Congressional District.