GE Aviation opens Alabama factory complex to produce unique materials for jet engines

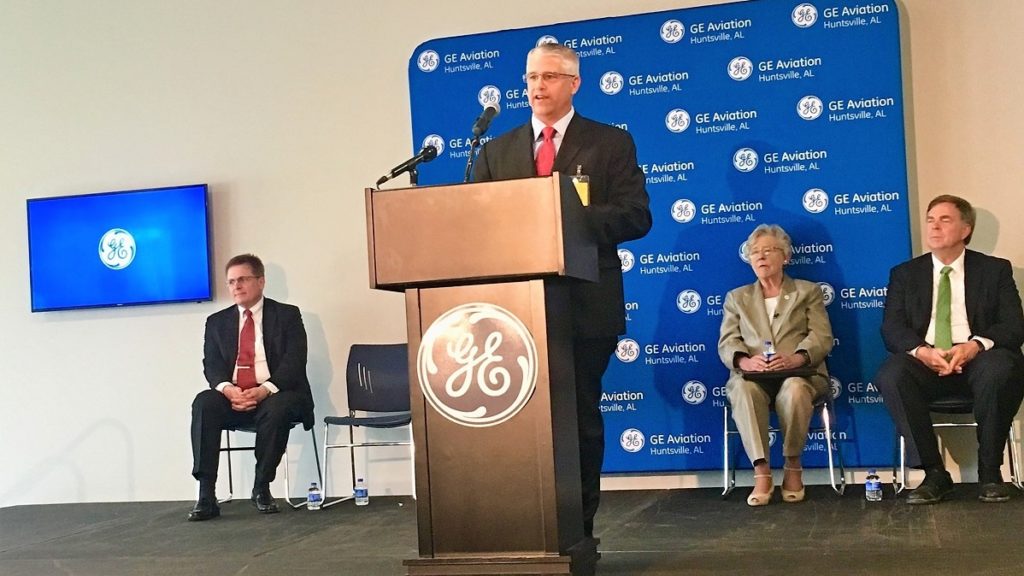

GE Aviation opened a factory complex in Alabama this week that will be the only U.S. location to produce unique materials used to manufacture ceramic components poised to revolutionize jet propulsion. The center in Huntsville comprises two adjacent factories standing on 100 acres, where silicon carbide (SiC) materials will be mass produced. The plants are critical in enabling GE Aviation to produce ceramic matrix composites (CMC) components in large volume. CMCs have ultra-lightweight properties and can withstand extremely high temperatures, making them an ideal material for use in the hottest portions of jet engines. “After years of research and testing, GE Aviation and our partners have cracked the code on mass producing CMC material,” GE Aviation executive Mike Kauffman said at a plant-opening ceremony Wednesday. He added, “The impact of these materials will be felt around the globe.” Aerospace leader GE Aviation executives joined Gov. Kay Ivey and state and local officials at the plant-opening ceremony, which comes more than two years after the company announced the project. “Alabama is recognized as a leader in the aerospace industry, and Alabamians are setting the standard in aerospace manufacturing, development and maintenance,” Ivey said. “When a company with a reputation like GE Aviation chooses to locate in our great state, it says a lot about our state and the quality of our workforce.” GE Aviation employs 90 people at the Huntsville production site, a number that is expected to double in the coming year. At full production, employment should reach 300. Production is projected to begin at the sprawling facility in the fourth quarter. Investment in the project has already exceeded $150 million and is expected to reach $200 million. “This is a great day for the State of Alabama. This is a great day for the City of Huntsville. This is a great day for GE Aviation,” Huntsville Mayor Tommy Battle said. “The partnership that we will build over the years is a partnership that will help each of us succeed.” Cutting-edge factories At the Huntsville plant complex, one factory will produce SiC ceramic fiber, the raw material used to make the unidirectional CMC tape being produced in the neighboring factory. The CMC tape will be used to fabricate CMC components for jet engines and land-based gas turbines. CMC components are much lighter than conventional jet engine parts while also being able to withstand extremely high temperatures. (GE Aviation) The fiber plant is modeled after the SiC fiber factory of NGS Advanced Fibers in Japan, a joint company of Nippon Carbon, GE and Safran of France. The expanding NGS operation is the only plant in the world today producing CMC fiber on a large scale. Demand for CMCs is expected to grow tenfold over the next decade, driven by rising jet engine production rates. This is not GE Aviation’s only cutting-edge Alabama factory. The company also produces fuel nozzles for next-generation LEAP engines using additive manufacturing at a facility in Auburn. This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website. Republished with permission from the Alabama NewsCenter