South Alabama students turn toy vehicle into learning tool for children with disabilities

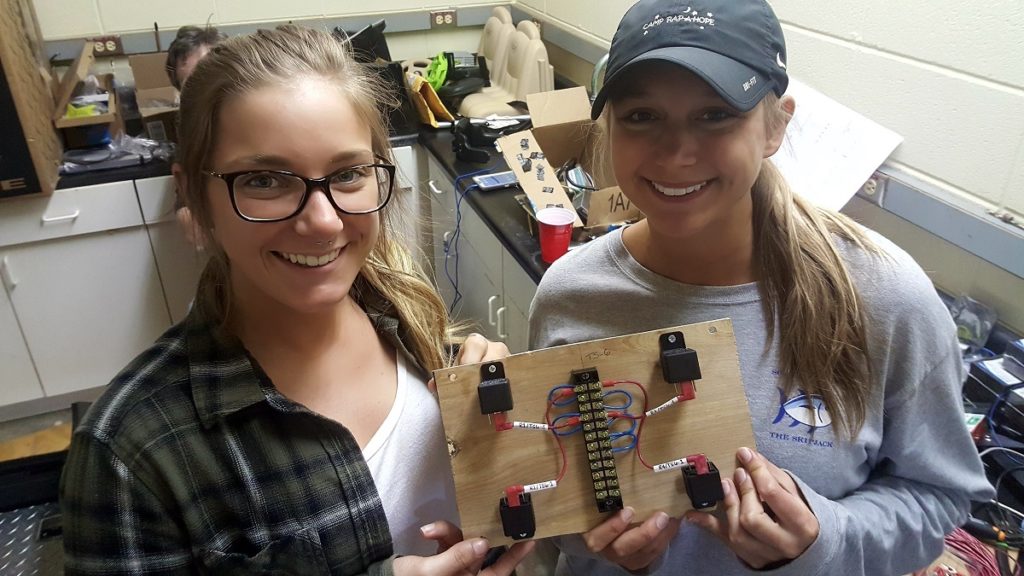

It started out as a senior project, and it ended up helping change lives. Every fall semester, senior engineering students at the University of South Alabama receive a list of group projects to consider for their Senior Design Capstone Project. “Students by this time have learned theory and ‘how-to,’” said Dr. David Nelson, professor and chair of mechanical engineering. “Now, they have to design it. In doing so, they can make a difference in someone’s life. It’s a great teaching tool.” For the 2016-2017 academic year, one of the chosen projects was undertaken with input from Hargrove Engineers and Constructors in Mobile. A Hargrove employee had learned of a handicapped child who needed a powered wheelchair and, through the Hargrove Adaptive Toy – or HAT – Project, contacted USA. The HAT Project, which was launched in 2016, takes off-the-shelf toy vehicles and modifies them for children with disabilities to practice with as they prepare to possibly use a powered wheelchair. “There are a number of children with disabilities who could benefit from a powered wheelchair, but a client must show they have the dexterity to operate it,” Nelson said. “Kids who’ve never used one are unlikely to pass the test to get one, so we wanted to provide a platform for them to practice.” “Reaching out to the USA College of Engineering was a natural fit,” said Michelle Jones, instrument engineer at Hargrove and executive director and project manager for HarGIVES, the company’s volunteer organization that sponsors the HAT Project. A College of Engineering graduate, Jones noted that Hargrove employs more than 100 South Alabama graduates. One of its more recent hires is Kent Bailey, a mechanical/piping engineer who graduated from USA last year after working on the HAT Project. The capstone project team included USA students from both mechanical and electrical engineering. “There were two challenges that really stood out,” Bailey said. “First, we, as mechanicals, had to have a basic knowledge of how the controls on the car worked, and that was a completely different language for us, so following what the electrical team was doing was difficult at times. “We also had challenges with scheduling,” Bailey continued. “With the electrical team having a different class schedule than us, we ran into an issue with when we could all get together. Building the car after we got the design finalized caused scheduling challenges as well, since the design was and still is evolving to adapt to different children. There were several instances when the mechanicals would have something in place and it would have to be modified to accommodate an update from the electricals.” Dr. Samuel Russ, associate professor of electrical engineering, underscored how valuable this type of collaborative effort is for future engineers. “The most important lesson the electrical engineers had to learn was that the work they did, such as selecting connectors and designing wiring, directly affected the mechanical engineers. So they had to learn to stop and ask, and they had to learn to respect the work of other engineering disciplines well enough to ask for their input. That sounds easy, but it is surprisingly hard to get engineers to do that.” Overcoming the challenges, the USA team successfully delivered its modified toy vehicle to Hargrove. “USA’s student team improved upon our original design and we used their changes to build eight cars last year,” said Hargrove’s Jones. “What sets many graduating seniors apart is experience – experience and passion,” Jones continued. “The HAT Project partnership gives real-world project exposure to these students that can make their resume stand out as well as give them a project to showcase in the interview process. That experience is invaluable. Retrofitting these toy cars for children with special needs is no easy task – it takes hard work, and hard work and the student’s dedication builds character. Many times, it is your character that helps students land good jobs – not just your skills.” For former students such as Bailey, it goes even deeper than practical experience and an edge in a competitive job market. “The personal satisfaction of having a finished deliverable was something the team always talked about and was motivation to make sure we provided the best product possible,” Bailey said. “It didn’t really sink in until I walked into the courtyard here at Hargrove one afternoon and saw a young lady driving the car that we built. There are not words to describe the excitement, not only on her face, but on her parents’ faces, too. Seeing that made every early morning and long night that we put into that car worth it, many times over.” According to Jones, through the volunteerism of South Alabama students, the HAT Project has been able to give eight specially designed cars to local children and physical therapy offices in the community. USA students who worked on the HAT Project are: in mechanical engineering, Kent Bailey, Kayla Bray, Ben Breland, Julius Pugh and Heather Turner; and, in electrical engineering, Victoria Antell, Emaleigh Sargent, Heath Skelton and Joe Wachob. Republished with permission from the Alabama NewsCenter.