Meghann Bridgeman announced as next Alabama Film Office director

The Alabama Department of Commerce announced last week the selection of Meghann Bridgeman, president and CEO of Create Birmingham, as the next Director of the Alabama Film Office. With extensive experience in arts and economic development, Bridgeman will lead the state’s efforts to attract, support and promote general entertainment productions across Alabama. Bridgeman brings a wealth of knowledge from her work with Create Birmingham’s Film Birmingham Initiative, where she spearheaded numerous initiatives aimed at fostering creative industries and driving economic growth in the film industry. She has a proven track record of building public-private partnerships and collaborating with entertainment professionals and local communities to create opportunities for growth and innovation. In her new role, Bridgeman will oversee the Alabama Film Office, working to position the state as a premier destination for filmmakers and producers. She will begin her new duties in January 2025. Alabama Commerce Secretary Ellen McNair expressed her confidence in Bridgeman’s leadership and vision for the state’s entertainment industry. “Meghann’s background in creative industries and her passion for economic development make her the perfect fit to lead the Alabama Film Office,” Secretary McNair said. “We are excited about her innovative approach and her commitment to leveraging Alabama’s unique assets to attract more entertainment projects, which will ultimately benefit our local businesses and communities,” she added. The Alabama Film Office, which was established in 1978, has been instrumental in the development of the state’s film and entertainment industry. Over the past several decades, it has attracted a variety of high-profile productions, including films such as Big Fish, 42, and Selma. More recently, Alabama has been the site for a growing number of television productions, documentaries and independent films, which have contributed significantly to local economies through job creation, tourism, and infrastructure development. “In partnership with entertainment industry stakeholders across our state, I look forward to joining the Alabama Department of Commerce as the director of the Alabama Film Office,” Bridgeman said. “The entertainment industry has the power to spark transformational economic growth, and Alabamians should be the beneficiaries of that growth. “I am grateful to Secretary McNair for the opportunity to lead this important effort and excited for the work ahead,” she added. The state’s film incentive program, which includes a competitive rebate structure, has helped to establish Alabama as a compelling destination for production companies. These incentives, along with the state’s diverse locations ranging from picturesque coastlines to historic cities, have made Alabama a go-to option for filmmakers seeking authentic, versatile backdrops. Last year, the industry spent nearly $60 million in Alabama on entertainment productions that included The Rivals of Amziah King, starring Matthew McConaughey and Kurt Russell, and The Shift, featuring Sean Astin. Rebates valued at $16.5 million were extended to productions in 2023, according to data from the Alabama Department of Commerce. Under Bridgeman’s leadership, the Alabama Film Office will continue to build on its success by strengthening partnerships with industry stakeholders, expanding production opportunities, and ensuring that Alabamians benefit from the state’s growing entertainment sector. Future plans could include expanding the office’s traditional focus to encompass additional forms of entertainment, including music productions and video games. The office will also maintain a concentration on workforce development and training, ensuring that Alabama remains competitive in the fast-evolving film and media industries. The Film Office’s longtime director, Kathy Faulk, will remain in charge of the office in the interim. “Kathy’s contributions to the Film Office have been significant over many years, and she has been an untiring champion for expanding Alabama’s presence within the entertainment industry,” Secretary McNair said. “Thanks to her, the Film Office is positioned for exciting new developments in the future.” This story originally appeared on Made in Alabama written by Jerry Underwood. Made in Alabama is a project of the Alabama Department of Commerce.

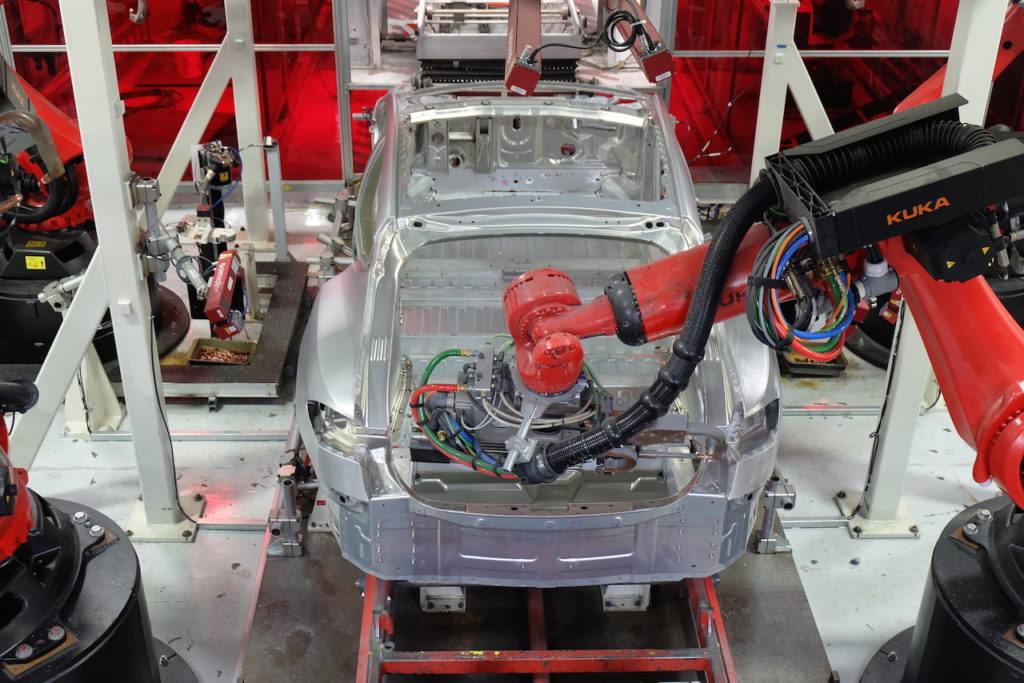

Aerospace, automotive summits heading to Birmingham this week

Birmingham is hosting a pair of business summits this week that showcase Alabama’s growing automotive and manufacturing industries, providing participants with high-level networking opportunities and one-on-one meetings. The conferences are the Aerospace Innovative Technology Summit (AITS), held May 7-9, and the Automotive Advanced Technology Summit (AATS), held May 8-9. Both events are taking place at the Birmingham-Jefferson Convention Complex, with 200 companies expected to participate. The Alabama Department of Commerce is among the sponsors of the summits, which feature workshops, presentations and business-to-business meetings. “The automotive and aerospace industries are major drivers of economic growth in Alabama, and these business conventions in Birmingham offer a pathway for companies from across the country and around the world to seek new opportunities and understand how their peers are utilizing and advancing the latest technologies,” said Greg Canfield, secretary of the Alabama Department of Commerce. “Besides companies from Alabama and multiple U.S. states, an international presence representing 11 different countries is here to participate,” he said. “These summits bring a focus on innovation, which is critical to growing and sustaining these manufacturing sectors and placing Alabama in a leading role for the latest technologies.” Focusing on innovation The Aerospace Innovative Technology Summit targets the aerospace, space and defense industries, all with a significant presence in Alabama. With a focus on new technologies being deployed in the sector such as 3D metal printing, digitalization of manufacturing and cyber security, the event aims to connect leading companies and participants in the sharing of ideas in the application and development of these innovations in their businesses. To kick off the aerospace conference, Canfield will provide an overview of the industry sector in the state. Other scheduled speakers include R.G. “Corky” Clinton Jr. of NASA’s Marshall Space Flight Center, Nick Bowman of GKN Aerospace and Jeff Chang of Lockheed Martin. The Automotive Advanced Technology Summit will focus on advanced manufacturing and new technologies at use within an industry growing rapidly in Alabama. Scheduled speakers include Mark Brazeal of Mazda Toyota Manufacturing USA, Tom Shoupe of Honda of America Manufacturing, and Brad Newman of ZF Chassis Systems in Tuscaloosa. Also speaking is Chuck Ernst, a former Honda Alabama executive who now serves as manager of the Alabama Robotics Technology Park, a unique training facility in Decatur. “It is an honor to have Birmingham chosen as the site for both of these conventions,” said Brian Jennings, vice president of economic development for the Birmingham Business Alliance (BBA). “It speaks to Alabama’s prominence in both the aerospace and automotive industries, and we look forward to bringing so many people together to foster continued growth of both industries.” Joining the BBA and the Department of Commerce in supporting the business conferences are the City of Birmingham, Jefferson County, the Birmingham Airport Authority, the Alabama Automobile Manufacturers Association and the Alabama Community College System. Mayor Randall Woodfin said Birmingham is the ideal location for the events. “Now, more than ever, Birmingham is focused on bringing high-quality technology jobs to our city. The summit gives a great chance to identify innovative partners that share our commitment to the next generation of manufacturing in the aerospace and automotive industries,” Woodfin said. This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

Need a last minute gift? Check out the Made in Alabama 2017 Holiday Gift Guide

Alabama is an internationally known hub of manufacturing for cars, planes and ships, but the state also turns out an impressive variety of items that fit perfectly underneath the Christmas tree. For the 2017 edition of the Made In Alabama holiday gift guide, we turned to the people who know the state’s creativity and craftsmanship best. (Here’s the 2016 installment.) We asked Alabama makers and artists to name their favorite local products – aside from their own – that they like to give as Christmas gifts. Anna Brakefield, owner of Red Land Cotton in Moulton, is a big fan of her peers’ work and had a few suggestions. Montgomery-based Alabama Sweet Tea Co. topped her list. Founded in 2015, the company was inspired by the founders’ memories of enjoying homemade sweet tea at family gatherings. Their own recipe is a custom blend of high-quality loose-leaf tea leaves, pure cane sugar and hand-squeezed fruit juice. “The sweetest and most humble people you may ever meet brew the sweetest tea known to the South and specifically Alabama,” Brakefield said. “Their boxed tea is a great gift to include as a stocking stuffer or in a care package to remind a loved one of their sweet Southern roots or to give them a little taste of the South.” Alabama Sweet Tea Co. also sells glasses, tumblers, shirts and hats emblazoned with the company logo. Another favorite of Brakefield’s is Idyllwilde, a design company and workshop studio based in Florence. Its clothing, accessories and items for the home are made from natural-fiber textiles and plant-based dyes. “A lot of amazing talent comes out of Florence, Alabama, and this shop is no exception. Their simple pieces are custom made, so there is a delay in shipping, but it’s worth the wait!” Brakefield said many items are hand dyed in small batches and truly are works of art. “The South has a rich textile history, and so giving a piece of Idyllwilde’s clothing or home accents is like sharing a little piece of that history with a friend,” she said. As for Brakefield’s own business, Red Land Cotton sells bedding, bath towels and other linens made from cotton grown in North Alabama. She and her father, Mark Yeager, own the business, with a farm that has been in the family for three generations. Their heirloom-inspired bed linens are recreations of those passed down from ancestors a century ago. Coffee and cookies Other Alabama makers also shop local at gift-giving time. Robert Armstrong, founder of G Mommas Cookies in Selma, picked a hometown favorite. “My top gift would have to be Revival Coffee – great coffee and great mission as well,” he said. The small-batch roaster, which opened in 2014 in Selma’s historic district, says its purpose is to see lives redeemed, and 10 percent of its profits are dedicated to Christian ministries. Revival offers several varieties of blends, including Integrity, Redemption, Restoration and Salvation. As for G Mommas Cookies, Armstrong said business is growing. He’s working on introducing a new flavor and upgrading equipment. The company has also expanded to three full-time and seven to nine part-time employees. Armstrong was inspired by his grandmother’s cookie recipe when he founded Selma Good Co., maker of G Momma Cookies, in 2009, and they have been sold in stores across the Southeast. Earlier this year, he took home the top prize of $107,000 in the Alabama Launchpad Competition, which funds entrepreneurs statewide. Socks and ornaments In northeastern Alabama, there’s mutual admiration between two well-known makers in Fort Payne. “Zkano socks would be an excellent gift idea,” said Cal Breed, owner of Orbix Hot Glass. The organic cotton socks are made in Fort Payne in an operation run by Gina Locklear, who is carrying on her family’s business and a community legacy. Fort Payne was once known as “The Sock Capital of the World” before offshoring dismantled the domestic industry. But Locklear’s socks have found a niche, with their bright colors, bold patterns, high-end quality and appeal to customers interested in green living. A year ago, Locklear was named a winner in the Martha Stewart American Made Awards, and just recently, she opened a store inside the Fort Payne sock mill. Meanwhile, Locklear said her favorite Alabama-made gift is Orbix ornaments. Breed and his crew fashion the ornaments, as well as bowls, vases, pitchers and other glass sculptures that have garnered international acclaim, in a studio atop Lookout Mountain near Little River Canyon National Preserve. The glass-blowing process is a delicate dance of fire, human breath and constant movement, and the studio hosts tours and sessions for visitors to blow their own ornaments. “I love them because they are collectible, uniquely beautiful and also, I love they are made in Fort Payne by kind folks I know,” Locklear said. More great gifts And if you’re still in need of gift-giving inspiration, here are a few more Alabama-made gifts to help check off your shopping list: Shadow Catchers Art: This longtime Greeneville company produces professionally framed and mounted artwork and wall décor for retail stores and design projects. The team works with designers, decorators and buyers to select images, moldings, mediums and mounting techniques. Its work spans a wide variety of interests, from botanical and nature scenes to coastal and cityscape images. Product types include acrylic, canvas, lithograph, mirrors and more. Earthborn Pottery: Top chefs across the U.S. and beyond have come to depend on owner/designer Tena Z. Payne and her Leeds business for striking pottery to frame their culinary creations. Each plate, bowl or mug is a functional work of art, and they can be found in restaurants and retailers nationwide. Three generations work together in the family-run, woman-owned business. Made By AK crafts jewelry that is minimal, modern and distinctive, making it another favorite of Brakefield’s. “When you attend craft shows there are a lot of jewelry makers. To me, Made By AK stands out. It’s truly unique. It’s bold but intricate and the pieces are made from high-quality materials. Handmade in Birmingham, AK’s jewelry is crafted by hand and inspired by life’s little imperfections, and that’s something I feel we can all

Alabama exports surging in unexpected corners of the world

It’s clear that 2016 was a stellar year for Alabama exports, with rising shipments in a number of markets worldwide, signaling even more optimism for the future. The top five destinations for state goods and services – Canada, China, Germany, Mexico and the United Kingdom – remained relatively unchanged from 2015 and most showed year-over-year growth. Overall, Alabama-made goods were shipped to 189 countries. A number of them, while not among the top five, showed significant growth in 2016, including Kuwait, Russia, Taiwan and the United Arab Emirates. The Alabama Department of Commerce is always studying trade trends among state businesses and manufacturers, using the information to plan seminars and trips aimed at helping companies boost their export business, said Hilda Lockhart, director of Commerce’s Office of International Trade. Economic engine With Alabama’s 2016 exports reaching a record $20.55 billion, increasing 6.4 percent from the previous year, officials are looking to build on that momentum, Lockhart said. “We know rising exports for Alabama companies in overseas markets means greater potential for new jobs and investment back home,” Lockhart said. “International trade is truly a local economic engine, and Alabama workers and communities benefit from the growth.” U.S. Commerce Department figures show the state’s exports have risen 15 percent since 2011 and 48 percent since 2006. Vehicles are the state’s top export, by a large margin. Other key categories include chemicals, primary metals, paper products and non-electrical machinery, a category that includes combustion engines, agricultural machinery, metalworking machine tools and much more. Lockhart offered a closer look at some of the fastest-growing markets for Alabama exports, and what’s driving them: KUWAIT: Alabama’s exports to the Persian Gulf country increased to $104.9 million in 2016, a 285 percent spike from the previous year. The largest increases were in fabricated metal products, chemicals and paper. “This year Alabama was Kuwait’s No. 1 trading partner in the nation for fabricated metal products, perhaps due to the country’s recent expenditures on various hydrocarbon and petrochemical refineries, such as the $10 billion Olefins 3 plant,” Lockhart said. Currently in the pre-execution phase, the Olefins 3 plant will produce 1.4 million tons of ethylene a year when it is completed. The petrochemical is commonly used in the manufacturing process. RUSSIA: Shipments of state exports to Russia rebounded in 2016 to $102.1 million, after a poor showing the previous year, with major increases in the export of non-electrical machinery, chemicals and paper. Alabama was Russia’s No. 5 trading partner among U.S. states for non-electrical machinery products.Russia’s demand for machinery is “driven by the government’s strategy to modernize Russian industry across several sectors, including power generation, transportation, defense, automotive and aerospace,” according to the U.S. Foreign Commercial Service. Lockhart said the drop in exports in 2015 likely occurred because of the contraction in the price of oil that year, which caused a recession in Russia and other oil-producing countries. TAIWAN: Exports from Alabama to Taiwan nearly doubled in 2016, increasing to approximately $200 million. The largest gains were in chemicals, computer and electronic products, and paper. “Chemical exports alone accounted for more than half of the 2016 total, showing a two-year increase from $19.6 million in 2014 to $102.7 million in 2016,” Lockhart said. The state was Taiwan’s No. 6 trading partner in the nation for chemicals, predominantly in the category of basic chemicals, which include industrial gases used in the semiconductor production process. Lockhart said the semiconductor industry, including manufacturing, design and packaging, is a cornerstone of the Taiwanese IT economy, so it is likely that the increased exports are feeding into this sector. UAE: Alabama firms shipped $467.8 million in exports to the United Arab Emirates in 2016, an increase of more than 100 percent compared to exports just two years earlier. Much of the growth took place in the categories of transportation equipment, non-electrical machinery and chemicals. The state was the UAE’s No. 5 trading partner in the U.S. for transportation equipment, with this category alone accounting for $396.2 million of the export total for the year. “Aerospace products make up the bulk of these transportation equipment exports as the UAE develops its burgeoning satellite and Mars mission programs, expands its military and increases investment in the commercial airline industry,” Lockhart said. Meanwhile, other up and coming markets have shown significant growth over the past five years, and they could be potential targets of new, increased efforts to fuel trade, Lockhart said. The countries include Vietnam, Oman, the Bahamas, Denmark, Finland, Kenya, Liberia, Hungary and Bosnia-Herzegovina. This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website. Republished with permission of Alabama NewsCenter.

Leonardo plans to produce advanced Air Force trainer in Tuskegee

Gov. Robert Bentley announced today that Leonardo, a global aerospace and defense firm, will create 750 jobs at an advanced assembly center at Tuskegee’s Moton Field if the company’s T-100 jet trainer wins a U.S. Air Force competition for a next-generation training aircraft. Bentley, Tuskegee University officials, Tuskegee Mayor Tony Haygood and community leaders joined executives of Leonardo at a ceremony at the airfield to announce plans for the Alabama manufacturing center. Moton Field, off Interstate 85 Exit 38, is home to the Tuskegee Airmen National Historic Site. This rendering shows Leonardo’s planned T-100 production center at Moton Field in Tuskegee. (Leonardo) The Leonardo project in Tuskegee calls for the creation of 750 high-wage, full-time jobs over a 10-year ramp-up period, beginning in 2019. Total investment in the T-100 project’s buildings, infrastructure and equipment would exceed $200 million to $250 million. “Leonardo’s project will have a massive economic impact in Macon County and across the region through the creation of high-paying jobs,” Bentley said. “Moreover, these T-100 training aircraft — built at the site where the legendary Tuskegee Airmen trained during World War II — will prepare a new generation of fighter pilots whose mission is to keep our country safe.” ‘World’s best trainer’ To establish its operation, Leonardo will lease a facility to be built at Moton Field by a public-private partnership formed in Macon County. The Alabama workforce will perform structural sub-assembly, integration and final assembly, and conduct research and testing at the site. Aircraft deliveries will also take place there. “Building the T-100 aircraft in Alabama will create American jobs while providing the Air Force with the world’s best trainer,” said Leonardo DRS CEO William J. Lynn, prime contractor for the T-100 team. “Future American military pilots can learn on the world’s most operationally proven, low-cost, low-risk integrated training system developed by a skilled U.S. workforce.” Leonardo’s twin-engine T-100 is being used to train pilots around the world to fly next-generation fighter aircraft. The trainer, based on the company’s proven M-346 aircraft, has been selected for this role by Italy, Israel, Singapore, the United Arab Emirates and Poland. T-100 partners Leonardo will be supported by Tampa, Florida-based CAE USA in the design and development of a comprehensive T-100 ground-based training system as part of the program. CAE has developed some of the most sophisticated simulation-based training systems in the world for fighter trainer aircraft, and it has been Leonardo’s partner on ground-based training systems for the M-346. The famed Tuskegee Airmen trained at Moton Field. (Contributed) CAE already provides a comprehensive training program to U.S. Army fixed-wing pilots at a high-tech $70 million center that opened recently at the Dothan Regional Airport. Honeywell Aerospace will provide the jet engines for the T-100 from its Arizona assembly plant. If Leonardo prevails in the Air Force competition, the company will join a robust and expanding aerospace industry in Alabama. The state is home to more than 300 companies and organizations involved in a full range of activities including aircraft and component assembly, raw materials production, engineering, maintenance and repair, and flight training. “Alabama has a long history of providing critical flight training for military aviators, and historic Moton Field is a perfect home for a facility where world-class training aircraft for U.S. fighter pilots are assembled,” said Greg Canfield, secretary of the Alabama Department of Commerce. “This is an ideal way to build on the important legacy of the Tuskegee Airmen.” ‘Generational game-changer’ Tuskegee and Macon County officials said the project could act as a powerful catalyst for growth. The Tuskegee Airmen National Historic Site. (Erin Harney/Alabama NewsCenter) “Tuskegee Institute was one of the very few American institutions to own, develop and control facilities for military flight instruction. Moton Field, named after Tuskegee University’s second president, was the Army Air Corps’ only primary flight training facility for African-American pilot cadets during World War II,” said school President Brian Johnson. The combat successes of these pilots, known as the “Red Tails,” led the way to the desegregation of the U.S. military in the late 1940s and provided a major spark for the Civil Rights Movement. “We look forward to supporting this effort that can lead to renewed vitality of Macon County and the city of Tuskegee,” Haygood said. “The collective efforts of our community to commit to world-class economic development through the MCEDA has shown what we can do together,” said Mark Ennis, chairman of the Macon County Economic Development Authority. “Leonardo and the T-100 project have been in the making for over two years. We stand side by side with them, ready to help them win and then build aircraft here in Macon County,” Ennis added. “This would be a generational game-changer for the future of our citizens.” This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website. Republished with permission of Alabama NewsCenter.

Dawn Azok: Japanese investment in Alabama fuels many industries

When it comes to Japanese investment in Alabama, auto manufacturers Honda and Toyota and their broad network of suppliers across the state immediately come to mind. But the Asian nation is behind a significant number of non-automotive companies here as well, from chemical and steel producers to pharmaceutical and life insurance firms. More than 140 Japanese companies call Alabama home, and their combined annual contribution to the state economy, from a consumer perspective, tops $200 million, said Mark Jackson, honorary consul general of Japan in Alabama. “It is a solid, proven base for Japanese investment to only grow bigger,” he said. “The Japan America story is tremendous, but I think the Japan Alabama story is even better.” Jackson is part of an Alabama delegation that visited Tokyo last week and participated in SEUS Japan 39, a high-level forum that aimed to strengthen cultural and economic ties. Greg Canfield, secretary of the Alabama Department of Commerce, and other Commerce officials were part of the delegation in Tokyo, where they visited Honda’s corporate headquarters. While there, Canfield presented Honda officials with a hand-crafted glass sculpture from Orbix Hot Glass in Fort Payne. The Commerce team also engaged in meetings with representatives of Unipres, an auto supplier with an operation in Steele, and others. Business connections Last year alone, 19 new and expanding Japanese companies and joint ventures announced more than 700 new jobs and new investment topping $365 million, according to Alabama Department of Commerce data and the Japan-America Society of Alabama. They included Pharmavite, a dietary supplement manufacturer in Opelika that is a subsidiary of Japan’s Otsuka Pharmaceutical Co., and southwest Alabama carbon steel processor AM/NS Calvert, a joint venture that includes Japan’s Nippon Steel. In other recent moves, Japan’s Dai-ichi Life Insurance Co. completed its purchase of Birmingham’s Protective Life Corp. last year, a $5.7 billion deal. Shortly after the merger was completed, the companies announced $4.1 million in donations to medical research, education and cultural organizations in Alabama. Elsewhere, other Japanese companies are also actively contributing to their communities in Alabama. In Decatur, for example, chemical firm Daikin and Toray, maker of carbon fibers and fluorofibers, continue to grow their businesses and shape the region, said Jeremy Nails, president and CEO of the Morgan County Economic Development Association. “Every year Daikin America hosts the Daikin Festival, a free event to educate our community on Japanese culture that often boasts attendance of more than 20,000,” he said. “Daikin also donated funds to add the Daikin Amphitheater to downtown Decatur, allowing the city much-needed space for events.” “Toray is the annual title sponsor of the Dragon boat race where 75 teams compete and raise over $150,000 for the local hospital,” Nails added. Daikin added 20 jobs in 2014 amid plant expansions in Decatur and has been in a continuous growth mode since starting up in the early 1990s. Today the company has 370 employees, and this year marks its 25th anniversary in Alabama. Toray currently has 320 employees at its carbon fiber plant and 53 at its fluorofiber plant, both in Decatur. To date, Toray has invested more than $500 million in its Decatur plants. Rewarding relationship “We have gone from becoming mortal enemies to global trading partners, and together we have built two of the strongest economies in the world,” he said.Jackson, the honorary consul, said it’s remarkable to consider the current relationship between the U.S. and Japan, since the countries were on opposite sides of World War II just a few generations ago. Jackson credits Sister Cities International, a citizen diplomacy program instituted by President Dwight D. Eisenhower in the 1950s, with helping spur not only cultural understanding but also economic cooperation with markets around the globe, including Japan. Cities across Alabama participate in the program, and several have sister cities in Japan. Since 1999, when Honda announced plans for its auto assembly plant in Talladega County, Japanese companies have invested more than $5 billion in the state, according to Alabama Department of Commerce figures. Toyota is celebrating its 15th anniversary in Huntsville this year. The $864 million engine factory has expanded four times since its groundbreaking in 2001 and employs around 1,350 people. A recent study showed Honda’s sprawling $2 billion plant generated $6.8 billion in economic activity in the state last year. Along with its Tier 1 suppliers, the automaker is responsible for more than 43,000 jobs and 4.4 percent of the state’s total annual output of goods and services. The Alabama delegation in Tokyo included more than 30 government officials, economic development professionals and others who work in finance, manufacturing, medical technology and tourism. Regions Financial Corp. executive John Turner was co-chairman of SEUS Japan 39. The delegation took part in sessions on environmental innovation as well as investment and trade, and members networked with Japanese business and government leaders. ••• This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

Robert Bentley signs Alabama Renewal Act into law

Joined by other state and local leaders at the Port of Mobile, Gov. Robert Bentley on Friday signed the Alabama Renewal Act into law. As part of the state’s continued commitment to job creation the legislation creates two new tools for increasing economic development: it will “increase the availability of shovel-ready land sites for job creation” and “stimulate cargo traffic at the state’s port facilities and connect Alabama businesses to new opportunities around the world via a new Port Credit.” Because most states already offer such incentives, the new legislation will make Alabama more competitive by providing more options for luring in large companies and new jobs. “The Port of Mobile is a critical and valuable asset for industrial transportation of goods on the global market,” Bentley said at the event. “The signing of the Alabama Renewal Act is another clear signal that Alabama is serious about economic development and remains competitive nationwide. We have made great strides in how we recruit and retain companies in our state, and I am pleased to sign the Alabama Renewal Act to continue our efforts of job creation and promotion of our ’Made In Alabama’ brand.” The legislation was sponsored by state Rep. Mac McCutcheon (R-Huntsville) and state Sen. Greg Reed (R-Jasper), who both joined Bentley at Friday’s event. “I would like to thank Governor Bentley and the members of the Legislature for supporting this bill,” McCutcheon said. “This measure will not only stimulate economic growth in our state but also promote the use of our state docks, which are second to none in the world.” “Our economy is improving, and I am committed to doing everything possible to create more jobs, especially in rural Alabama,” said Reed. “The Alabama Renewal Act will help us achieve that goal while being fiscally responsible to taxpayers.”