Toyota, Mazda said to narrow choice to North Carolina, Alabama for $1.6 billion plant

Alabama and North Carolina are the final states in the running to win a prized Toyota and Mazda car factory worth $1.6 billion, according to people familiar with the negotiations. The automakers have been narrowing the list for weeks, knocking out almost a dozen other contenders that until recently included Tennessee, Texas and South Carolina, the sources said. Mazda and Toyota plan to announce their final choice by early next year, Akira Marumoto, Mazda’s executive vice president, told reporters in Tokyo earlier this month. Scott Vazin, a Toyota spokesman, and Jeremy Barnes, who represents Mazda, both declined to comment. The shared factory, scheduled to open in 2021, is the first new auto assembly plant to be announced during the tenure of President Donald Trump, who has pressured Toyota and other carmakers to make more of their vehicles in the U.S. During his recent visit to Tokyo, Trump thanked executives from the two companies for planning 4,000 new jobs at the plant. “That’s big stuff,” Trump told them, according to The Washington Post. Toyota and Mazda are pressing for an incentive package valued at $1 billion or more for the factory that is such a hotly contested prize. Mazda, which imports all the models it sells in the U.S., plans to produce crossovers alongside Toyota Corolla compact cars at the new plant. In October, Toyota reduced the size of its initial investment in a new plant in Mexico. The company will spend $700 million on the Guanajuato factory instead of the $1 billion it originally pledged, and production will be 100,000 vehicles a year instead of 200,000. Trump had criticized Toyota’s Mexico plans in a tweet in January, demanding Toyota build a plant in the U.S. instead. Republished with permission from the Alabama NewsCenter

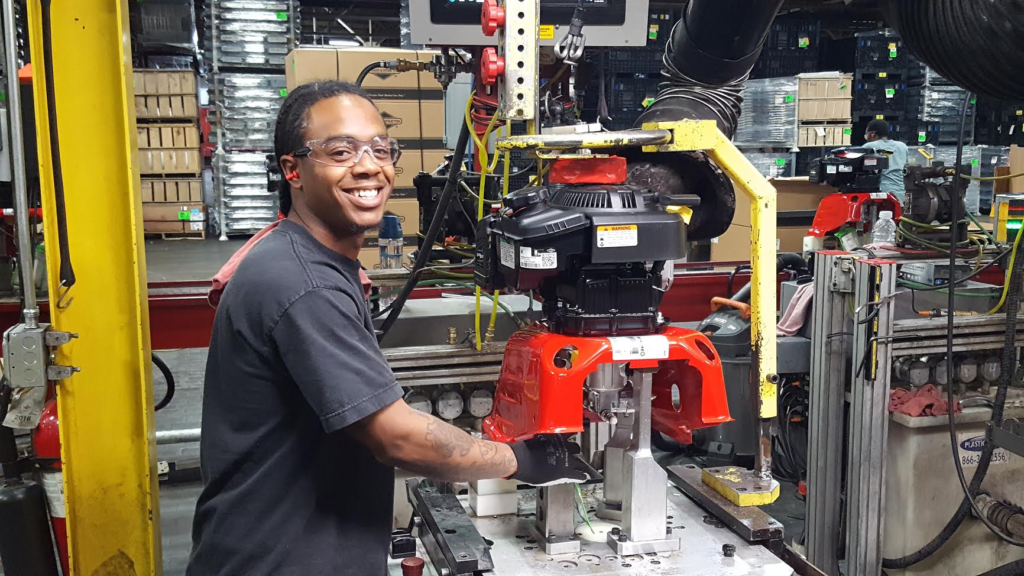

Briggs & Stratton makes $12 million investment in Alabama expansion, creating 50 jobs

The Milwaukee-based Briggs & Stratton Corporation announced on Monday it will move production of its Vanguard big block V-twin engines from a joint venture partnership in Japan to its existing manufacturing facility in Auburn, Ala. in 2018, ultimately creating approximately 50 new jobs for the area. The project involves a $12 million investment from the company. “Briggs & Stratton is a valuable, longtime member of Alabama’s business community, and the company’s decision to expand its product manufacturing in Auburn is a testament to the strong partnership we have developed together over the years,” Governor Kay Ivey said of the announcement. “I’m committed to creating an ideal environment for commerce and letting the world know that Alabama is open for business.” Briggs & Stratton worked closely with state officials in Alabama and Georgia, where the company will also expand a plant in Statesboro, to ensure a collaborative transition. “Moving production of the Vanguard Small and Big Block V-Twin engines to the U.S. is another step in the execution of our commercial growth strategy,” states David J. Rodgers, senior vice president and president – Global Engines & Power. “We see this as a strategic competitive advantage because we can manufacture closer to our customers in the U.S., resulting in faster production times and faster shipping.” Auburn Mayor Bill Ham congratulated the team at Briggs & Stratton for its success and gaining the new product line for the facility. “We are truly grateful that the leadership at Briggs & Stratton continues to trust our community with their investment,” said Ham. “The contributions to our economy and the lives of our citizens cannot be overstated. From providing jobs to helping fund our annual Fourth of July fireworks display for many years running, they are an outstanding corporate member of the community.” Briggs & Stratton, which has operated in Auburn for 22 years, is one of the city’s largest industrial employers, with 430 workers. “I would like to extend a thank you the Alabama Department of Commerce for their overwhelming support, which has helped enable us to not only grow and compete, but also to strengthen our connection with the communities,” Rodgers added. Greg Canfield, secretary of the Alabama Department of Commerce, said the addition of the new product line at the Auburn facility reflects the high level of confidence the company has in its Alabama workforce. “A top priority for Alabama’s economic development team is to support world-class companies like Briggs & Stratton that are looking to expand in the state, and one of the most important resources we have in that mission is Alabama’s highly skilled workforce,” Canfield said.

Manufacturing jobs on rise in Dothan area

Manufacturing jobs are on the rise in southeast Alabama. The Dothan Eagle reports that Houston County experienced a 21 percent increase in manufacturing jobs within the past year. It topped all other counties in Alabama by a substantial margin. Greene County experienced the second-largest increase at 15.5 percent. In the past year, Houston County’s unemployment rate fell from 6.1 percent to 4.2 percent. About 1,400 more jobs exist in the area. Dothan Area Chamber of Commerce president Matt Parker says the biggest percentage of growth occurred in the 22- to 24-year-old sector. He attributed that success to partnerships with Alabama Industrial Development Training, the Alabama Department of Commerce, Dothan Area Career Center and Wallace Community College and investments in programs like Southeast Alabama Works and K-12 programs. Republished with permission from the Associated Press.

Twinkle Andress Cavanaugh: ‘Buy America’ policy is important for Alabama jobs

This Labor Day weekend, Alabamians will celebrate the end of summer and the start of another college football season. While we gather with family and friends, I hope we will also reflect on the importance of supporting Alabama jobs and the contributions American workers continue to make to our economy. Since I first became active in public service, job creation and growth have been two of my primary objectives. As I continue to serve Alabama, my goal is to create a healthier economy and facilitate job growth in all corners of the state. Jobs must be our primary focus, whether in farming, manufacturing, coal mining, the iron and steel trades, or any other industry in our state. For more than 150 years, Alabama’s steel manufacturing industry has been a driving force behind our state’s economic growth; providing a solid workforce and job opportunities to thousands of hardworking Alabamians. Today, I would like to particularly highlight the continued importance of this Alabama industry. According to the American Iron and Steel Institute, over 60,000 Alabama jobs are supported by the steel industry. The strength of our domestic steel industry is vital to the health of our national economy and is directly connected to the economic wellbeing of local communities. The United States’ steel industry faces challenges, especially competing with foreign countries like China and Russia. Fortunately, we have opportunities to strengthen Alabama and America’s steel industry through ‘Buy America’ policies and the U.S. Department of Commerce’s investigation into Section 232 of the Trade Expansion Act. ‘Buy America’ is a policy that suggests we keep our tax dollars in our own economy to support state-funded projects; this creates jobs, boosts the local economy, and strengthens our national security. The National Association of Manufacturers states that manufacturing contributes $27 billion to Alabama’s economy each year, so by keeping that money in our own economy and supplying infrastructure projects with local materials, we are supporting our own hardworking citizens instead of relying on foreign countries. With the Section 232 investigation, the U.S. Department of Commerce is reviewing the impact that imports of steel and aluminum are having on the U.S. economy, national security and jobs. I hope the Department of Commerce will recommend action that will allow domestic steel producers in Alabama to continue to thrive. By doing this, we are implementing conservative policies that will have a direct impact on Alabama jobs. This will create a ripple effect that will have a positive impact on not just steelworkers, but their families, local communities and our economy. I am proud of the work that men and women across Alabama do to support steel manufacturing in our state and contribute to our local economy. As a state, we must continue to identify ways to improve our economy and infrastructure and develop a strong workforce. Let us keep that in mind as we enter the Labor Day weekend; making a conscious effort to invest in Alabama companies, grow jobs, and make improvements to our infrastructure that will strengthen the economy in our state and create opportunities for future generations. ••• Twinkle Andress Cavanaugh is the President of the Alabama Public Service Commission. Opinions expressed do not represent the position of the Public Service Commission or its other commissioners.

Alabama sleeping bag maker among American-made survivors

Entire industries, from textiles to toys, have become almost extinct in the U.S. as manufacturers moved abroad in search of lower costs or got swept away by a wave of imports. Some products aren’t Made in America at all anymore. Others still are – but by just a handful of small businesses, or maybe only one. They’re mostly surviving by the skin of their teeth in a world where shoppers care more about price than country of origin. Their stories show the challenge of producing at home – as President Donald Trump is pushing for – and also that it’s not impossible. Exxel Outdoors LLC Sleeping bag maker Exxel had about a half-dozen rivals in the mid-1990s, according to Chief Executive Officer Harry Kazazian. Most had moved overseas by 2000 when he and co-founder Armen Kouleyan bought the Haleyville, Alabama, factory. The company is now the largest sleeping bag manufacturer in the nation. “We’re proud that we’re the last man standing,” Kazazian says. “We stuck with it, and it paid off.” Since 2000, the factory’s employees have more than doubled to 95; they produce about 2 million sleeping bags a year. Import competition remains cutthroat in the below-$30 range for the high-volume, mass-retail business. Exxel makes its own brands, Disney– and Marvel-licensed ones, and retailers’ private labels. Wal-Mart Stores is its biggest buyer. Exxel added outdoor-gear brands such as Wenzel and Kelty with an acquisition in 2015, diversifying its offerings to include $689.95 Sierra Designs tents and $299.95 Slumberjack hunting backpacks. While many of Exxel’s products are produced in China, it makes more sleeping bags in America than overseas. They account for more than a third of annual sales, which exceed $100 million. In 2008, when the weakening dollar and rising foreign wages tilted the advantage toward U.S. manufacturing, Kazazian, 55, brought some production back from China. The factory has maximized automation, though workers do quality control and other tasks such as operating quilting machines. Ten-hour, four-day workweeks limit energy costs. The fiberfill, threads and packaging cartons are all bought from U.S. suppliers. Still, some things just aren’t done at home. When retailer demand for “Star Wars” sleeping bags surged late in the holiday season last year, Exxel tapped contract factories overseas to supplement its American production. Shells and carry-cases for the bags are imported as the necessary low-cost, polyester taffeta isn’t available here. As Kazazian says, “a percentage of something here is better than 100 percent of zero.” Dubuque Clamp Works Dubuque, Iowa, had a thriving industrial economy until the 1980s. Now, not so much. Keith Clark is still there, making woodworking clamps, as he’s done for four decades. The company he co-owns with his wife, Edna, has annual sales of $500,000, with customers from Germany to South Korea. Clark, 72, turns away new orders, partly because so much of the supply chain he relies on has moved abroad. Rivets and springs can take weeks to arrive. He often ends up making his own parts. “That’s the reason it’s going to be hard for manufacturing to come back,” Clark says. “You need all these sundry businesses to be here.” So Dubuque Clamp stays small by design, employing three people plus part-timers. It does some custom molding, but 90 percent of its output is specialized clamps for holding wood in place. The clamps are manufactured on about 50 dedicated machines and used to make everything from cabinets to countertops and guitars. “If a clamp isn’t perfect, it doesn’t go out. We just throw it away,” Clark says. “If anybody breaks a part, we just replace it, no questions asked.” That means higher price tags than mass-produced imports. On Amazon.com, his 6-inch handscrew clamp costs $24 – not the cheapest option, though not the most expensive either. Clark doesn’t see the need for his own website or any marketing; customer testimonials bring in plenty of sales. But “nobody in their right minds probably wants to do this anymore,” he says about the industry. “It’s too demanding.” One of his last U.S.-based rivals, which made Pony and Jorgensen clamps, was sold to a China-based buyer after shutting its business operations last year. Clark likens himself to “the last Mohican. Boy, that’s probably how they felt.” American Mug & Stein Co. “Everything is made the old way,” says owner Clyde McClellan, 68. “It’s not high-volume or mechanized.” Fifteen employees – down from 35 in the company’s heyday – cast ceramic mugs by hand into molds, then glaze and fire them in kilns. There’s rich clay to be found near American Mug’s base in East Liverpool, Ohio – known as the nation’s pottery capital in the 19th century. Foreign competition led to a steady erosion, and the last recession dealt another blow. American Mug and another firm are the only holdouts in town. McClellan, a 44-year veteran of the industry, bought the company in 2009. Then, in 2011, along came Starbucks Corp. The coffee chain was running a campaign to encourage American products, which led it to McClellan. “Starbucks came out of nowhere,” and suddenly there was hope, and more orders than ever, he recalls. The publicity around that deal has brought in almost all his new clients in recent years, McClellan says. “We’ve had to reinvent ourselves. Instead of having customers adapt to us, there are deadlines now,” and he’s more selective about accepting orders. Oktoberfest is the busiest time for beer steins, while coffee mugs are cranked out at maximum capacity all year. Starbucks still buys about 35 percent of them. The pottery’s special commemorative mugs have, through contractors, made their way to patrons such as the Smithsonian’s Hirshhorn Museum and the U.S. Navy. McClellan says he needs two more workers, but the region’s drug-abuse problem has made the search harder. “You need good hand-eye coordination” to avoid breaking things or wasting materials. His staff can earn as much as $13 an hour, though it’s in high temperatures, and “people don’t like to get their hands dirty” with clay these days. For every mug McClellan produces at a wholesale cost of $3.50, chain-store suppliers can get one from China at 85 cents to $1, decorate

Safran to open aerospace manufacturing facility at Mobile Aeroplex

French aerospace giant Safran plans to open a manufacturing operation at Mobile Aeroplex — home to the Airbus A320 Family assembly line — and hire 20 employees over the next three years, according to the Mobile Area Chamber of Commerce. The company will produce and install aircraft engine nacelles at this facility. Paris-based Safran is one of the world’s two leading integrators of aircraft engine nacelle systems, which house an aircraft engine and its related components. “Safran is excited to be part of the growing aerospace community in Mobile,” said Peter Lengyel, president and CEO of Safran USA. “We are pleased to move forward with this investment in Mobile.” To house the facility, the Mobile Airport Authority is building out one of the existing bays at Mobile Aeroplex to 24,500 square feet, according to the Chamber. In addition, the company is investing approximately $1 million in equipment, with an opening planned for November. Safran is the 19th company to locate at Mobile Aeroplex at Brookley since Airbus launched production in Alabama, said Mayor Sandy Stimpson. The company joins a growing list of aerospace companies with a strong presence in Mobile, with examples including VT MAE, Continental Motors and MAAS Aviation. “We are pleased and proud to welcome Safran to the family of aerospace companies choosing to invest in Mobile,” Stimpson said. “Mobile is open for business, and our future has never been brighter.” Air Show connection The announcement comes two months after a high-level delegation from Mobile met with Safran USA’s executives at the Paris Air Show. “It’s exciting to see Team Mobile once again successfully recruit another world-class aviation and aerospace industry partner to our area,” Mobile County Commissioner Connie Hudson said. The Mobile Area Chamber said discussions to locate the facility in Mobile were finalized at a meeting in Paris that included Safran USA decision-makers, Stimpson, Hudson and Mobile Airport Authority’s Mark McVay. “Safran is yet another worldwide company in the aerospace industry to call Mobile home. Their manufacturing presence within our aerospace hub will continue to pay dividends in our future recruitment efforts in the industry,” said David Rodgers, a senior project manager who led the recruitment efforts for the Chamber. Aerospace expansion Safran’s announcement comes amid a growth spurt for the Alabama aerospace sector. In 2016, aerospace firms announced projects involving $260 million in new capital investment and 2,000 jobs, according to Alabama Department of Commerce data. This year has brought a string of high-profile aerospace announcements from companies such as Blue Origin, Leonardo and Aerojet Rocketdyne. “Alabama is involved in virtually every aspect of the aerospace industry, from R&D activities and raw material production to aircraft assembly and component fabrication,” said Greg Canfield, secretary of the Alabama Department of Commerce. “This puts the state in a prime position for sustained growth in a dynamic industry.” This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

Airbus achieves a global first with Mobile production of its A320

With little fanfare, Airbus SE is about to mark an unusual milestone in aviation: simultaneous production of the same aircraft on three continents. The company will hand over the first A320 to roll out of its Mobile assembly plant on Aug. 25, meaning North America will join Europe and Asia in producing the most popular airliner in the world. The Alabama facility opened in 2015 and has thus far produced three dozen of Airbus’ larger A321s. The first U.S.-built A320 will be handed over Friday to Spirit Airlines Inc., which has ordered 98 of the planes. By year’s end, Airbus plans to reach a production rate of four aircraft per month at the Mobile facility. “The sun never sets on Airbus manufacturing!” company spokeswoman Mary Anne Greczyn wrote in an email. “Internationalization, coming closer to our customers, and a global industrial footprint are part of our overall strategy.” Airbus opened its first assembly plant outside Europe in 2008 in Tianjin, China, where it produces A319s and A320s; European A320 production takes place in Toulouse, France. The European company is also building a completion center in Tianjin for wide-body A330 models. The single-aisle A320 is the middle model in the Airbus family of jets favored for shorter domestic flights. The classic and new engine option (neo) versions, combined, are the company’s best-selling commercial aircraft, with a total of 8,421 orders, including a backlog of more than 3,800 as of July 31. Operations in China Chicago-based Boeing’s three aircraft assembly plants are all in the U.S., although the company broke ground in May on an interiors-completion center near Shanghai for 737 Max aircraft destined for China – which is seen as the largest source of aviation growth for the next 20 years. The 737 is Boeing’s best-selling and most profitable model, a direct competitor to the A320. When Boeing’s Chinese facility opens next year, 737 Max planes will be flown there for such final touches as seats, paint and carpet. “It’s stapling carpet, basically,” Richard Aboulafia, an aerospace analyst at Teal Group, said of Boeing’s China operation. “Up until Airbus, everyone that had moved a production line to China … regretted it almost instantly. And then Airbus stepped up to the plate and, strangely, got it right.” Before Airbus, the business of assembling aircraft in China has been financially fraught, with sales generally weak, he said. Last year, Brazilian manufacturer Embraer SA dissolved its Chinese joint venture, Harbin Embraer Aircraft Industry. Over 12 years, the firm produced 50-seat Embraer regional jets and several Legacy 650 business jets in China. In the late 1980s, McDonnell Douglas moved some of its single-aisle MD-80 and MD-90 aircraft production to China, but encountered weak sales and had to ship some planes back to U.S. customers, Aboulafia said. Boeing forecasts that the Asia-Pacific region will purchase more than 15,000 of the almost 40,000 new aircraft it foresees as global demand through 2035. The Asia market will need almost twice the number of airplanes as will be sold in North America, the No. 2 projected market. Boeing is about to increase its monthly 737 production to 47, from 42, and to 50 by the end of the decade to keep pace with surging demand. But Aboulafia says the company will almost certainly forgo any significant assembly work in Asia, a tactic other companies have used to boost Chinese sales. “I don’t think they think it’s worth it,” he said. “They’ve had fantastic success selling the 737 Max over there.” Republished with permission of Alabama NewsCenter.

Dawn Azok: Japanese investment in Alabama fuels many industries

When it comes to Japanese investment in Alabama, auto manufacturers Honda and Toyota and their broad network of suppliers across the state immediately come to mind. But the Asian nation is behind a significant number of non-automotive companies here as well, from chemical and steel producers to pharmaceutical and life insurance firms. More than 140 Japanese companies call Alabama home, and their combined annual contribution to the state economy, from a consumer perspective, tops $200 million, said Mark Jackson, honorary consul general of Japan in Alabama. “It is a solid, proven base for Japanese investment to only grow bigger,” he said. “The Japan America story is tremendous, but I think the Japan Alabama story is even better.” Jackson is part of an Alabama delegation that visited Tokyo last week and participated in SEUS Japan 39, a high-level forum that aimed to strengthen cultural and economic ties. Greg Canfield, secretary of the Alabama Department of Commerce, and other Commerce officials were part of the delegation in Tokyo, where they visited Honda’s corporate headquarters. While there, Canfield presented Honda officials with a hand-crafted glass sculpture from Orbix Hot Glass in Fort Payne. The Commerce team also engaged in meetings with representatives of Unipres, an auto supplier with an operation in Steele, and others. Business connections Last year alone, 19 new and expanding Japanese companies and joint ventures announced more than 700 new jobs and new investment topping $365 million, according to Alabama Department of Commerce data and the Japan-America Society of Alabama. They included Pharmavite, a dietary supplement manufacturer in Opelika that is a subsidiary of Japan’s Otsuka Pharmaceutical Co., and southwest Alabama carbon steel processor AM/NS Calvert, a joint venture that includes Japan’s Nippon Steel. In other recent moves, Japan’s Dai-ichi Life Insurance Co. completed its purchase of Birmingham’s Protective Life Corp. last year, a $5.7 billion deal. Shortly after the merger was completed, the companies announced $4.1 million in donations to medical research, education and cultural organizations in Alabama. Elsewhere, other Japanese companies are also actively contributing to their communities in Alabama. In Decatur, for example, chemical firm Daikin and Toray, maker of carbon fibers and fluorofibers, continue to grow their businesses and shape the region, said Jeremy Nails, president and CEO of the Morgan County Economic Development Association. “Every year Daikin America hosts the Daikin Festival, a free event to educate our community on Japanese culture that often boasts attendance of more than 20,000,” he said. “Daikin also donated funds to add the Daikin Amphitheater to downtown Decatur, allowing the city much-needed space for events.” “Toray is the annual title sponsor of the Dragon boat race where 75 teams compete and raise over $150,000 for the local hospital,” Nails added. Daikin added 20 jobs in 2014 amid plant expansions in Decatur and has been in a continuous growth mode since starting up in the early 1990s. Today the company has 370 employees, and this year marks its 25th anniversary in Alabama. Toray currently has 320 employees at its carbon fiber plant and 53 at its fluorofiber plant, both in Decatur. To date, Toray has invested more than $500 million in its Decatur plants. Rewarding relationship “We have gone from becoming mortal enemies to global trading partners, and together we have built two of the strongest economies in the world,” he said.Jackson, the honorary consul, said it’s remarkable to consider the current relationship between the U.S. and Japan, since the countries were on opposite sides of World War II just a few generations ago. Jackson credits Sister Cities International, a citizen diplomacy program instituted by President Dwight D. Eisenhower in the 1950s, with helping spur not only cultural understanding but also economic cooperation with markets around the globe, including Japan. Cities across Alabama participate in the program, and several have sister cities in Japan. Since 1999, when Honda announced plans for its auto assembly plant in Talladega County, Japanese companies have invested more than $5 billion in the state, according to Alabama Department of Commerce figures. Toyota is celebrating its 15th anniversary in Huntsville this year. The $864 million engine factory has expanded four times since its groundbreaking in 2001 and employs around 1,350 people. A recent study showed Honda’s sprawling $2 billion plant generated $6.8 billion in economic activity in the state last year. Along with its Tier 1 suppliers, the automaker is responsible for more than 43,000 jobs and 4.4 percent of the state’s total annual output of goods and services. The Alabama delegation in Tokyo included more than 30 government officials, economic development professionals and others who work in finance, manufacturing, medical technology and tourism. Regions Financial Corp. executive John Turner was co-chairman of SEUS Japan 39. The delegation took part in sessions on environmental innovation as well as investment and trade, and members networked with Japanese business and government leaders. ••• This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

Supersonic jet manufacturer eyeing Mobile as possible plant site

Aerion Corporation says they are considering the rising manufacturing hub of Mobile for a new American plant to produce parts for the state-of-the-art AS2 supersonic jet. Nevada-based Aerion is a contractor with Airbus, the French aerospace firm which designed the AS2, which can travel faster than the speed of sound, rendering a normally 12-hour trans-Atlantic flight just three hours long. An Aerion spokesperson, Jeff Miller, told CBS 5 in Mobile the firm is carefully considering its next plant location but that Alabama is very much in contention. “We are really going to do our homework and identify the best candidate cities with the right kind of airport and infrastructure. I will say Mobile cannot be excluded,” said Miller. “Mobile certainly has a number of attractive features, but it’s just too soon to start rating candidate cities,” Miller continued. Local aviation and municipal officials in Mobile have been mum on the project. “Any ongoing economic development project, we don’t comment one way or the other about it until a contract is signed,” Mobile Mayor Sandy Stimpson said Thursday. “We pursue everything that has to do with avionics right now…that’s really all I can say about that.” A spokesperson for the city’s Brookley Aeroplex – which meets many of the company’s specifications, including aerospace infrastructure and proximity to water – offered a similar response to inquiries this week. The aeroplex almost certainly would, however, benefit from an existing relationship with Airbus and related contractors within city limits. Aerion says the will to announce their location in early 2016 and begin construction in 2018. Miller said if all goes well, Aerion will start test flights in 2021 and hopefully start producing jets in Alabama by 2023. The plant would be a huge “get” for the local economy, recently buoyed by good regulatory and economic developments in the manufacturing sector.

Bradley Byrne: Manufacturing on the rise, but challenges remain

As I was touring the manufacturing operation at Quality Filters in Robertsdale, I was struck by just how much manufacturing has grown in Southwest Alabama over the last decade. I paid a visit to Quality Filters to help celebrate National Manufacturing Day, which took place on October 2nd. We have seen a large increase in manufacturing all over Alabama, driven by our growth in the motor vehicle, chemical, and aerospace industries. In 2014, over 250,000 Alabamians worked in manufacturing. These manufacturing jobs paid an average of $60,945 while the average pay for other non-farm businesses was $41,089. All told, manufacturing had a $34.4 billion impact on Alabama’s economy. Despite these impressive gains, manufacturers in Southwest Alabama and across the country are facing a wide range of challenges brought on by the federal government. Whether it is the EPA, IRS, NLRB, or OSHA, manufacturers must deal with regulations from an alphabet soup of federal regulators. Even if you don’t work for a manufacturer, that does not mean these regulations won’t impact you. The regulatory costs are often passed on to the consumer in the form of higher prices or fewer options. The Environmental Protection Agency (EPA) is likely the biggest foe of manufacturing. Given the nature of the industry, manufacturers use a third of our nation’s energy, so they depend on affordable energy prices. Unfortunately, it seems like every day the EPA is putting out a new regulation that will drive up energy costs. Take the EPA’s new ozone standard for example. The new standard is misguided and will be incredibly costly for our nation’s manufacturers. In fact, the new standard is so low that even some national parks could be out of compliance. At a time when ozone levels have already been reduced, it makes no sense to place additional burdens on our job creators. In Congress, I have been a strong supporter of the REINS Act. This commonsense legislation would require Congressional approval of any regulation with an annual economic impact of $100 million or more. Many of the EPA’s proposed rules would fall under this category, and I am certain the Republican-controlled Congress would stop these costly regulations from moving forward. The National Labor Relations Board (NLRB) has also attempted to increase the number of labor regulations impacting manufacturers. The NLRB’s “ambush elections” rule will shorten the time it takes to hold a union election and make the personal contact information of employees publicly available to union representatives. Earlier this year, the House and the Senate passed legislation to block the ambush election rule from going into effect. Unfortunately, President Obama vetoed the bill, and the Senate did not have the votes to override the veto. Despite that setback, we are continuing to push back against frivolous NLRB regulations on manufacturers. Another challenge to manufacturers comes in the form of a growing skills gap. Our nation is currently experiencing a shortage of skilled workers to fill certain manufacturing jobs. Without access to enough skilled workers, it’s becoming harder and harder for manufacturers to grow and expand their operations. As a member of the House Education and the Workforce Committee, I have made it a top priority to improve our nation’s job training programs. We need to encourage collaboration between the private sector and institutions of higher learning, specifically community colleges and trade schools. This will help close the skills gap and give more Americans access to high paying jobs. So while manufacturers are facing some significant challenges, there are also those of us in Congress who are committed to supporting manufacturing. So whether it is Quality Filters or other businesses in our area, I will do everything I can to support manufacturing and the thousands of jobs associated with the industry. Bradley Byrne is a member of the U.S. Congress representing Alabama’s 1st Congressional District.

Alabama business roundup: Headlines from across the state

Here’s a roundup of some of the weekend’s top business headlines from across the state: Alabama Newscenter: Business Facilities: Alabama ranks high for auto manufacturing, workforce development Alabama got high marks for “Automotive Manufacturing Strength” and AIDT, Alabama’s workforce development agency, ranked high among “Workforce Training Leaders” in Business Facilities magazine’s annual rankings report, released last week. Record output at Alabama’s three auto assembly plants underlined the state’s No. 2 ranking in the magazine’s “Auto Manufacturing Strength” category. Alabama and Tennessee swapped positions in the rankings from the previous year. “Alabama, this year’s No. 2, is throwing down a marker for a heavyweight rematch: the Crimson Tide rolled out nearly a million vehicles in 2014 for Mercedes, Honda and Hyundai, with Mercedes expanding at Tuscaloosa to introduce a new model,” Business Facilities noted in its ranking report. Alabama’s “world-class on-site training for advanced manufacturing,” is cited for a No. 2 ranking among “Workforce Training Leaders.” AIDT, which has trained 600,000 Alabamians since its founding in 1971, is a division of the Alabama Department of Commerce. “We’re proud of the efforts that these rankings represent,” Commerce Secretary Greg Canfield said. “But there is still much work to be done. With a new workforce incentive structure and a streamlining of resources, we’re poised for even greater things in Alabama.” Under Governor Robert Bentley’s leadership, Commerce is expanding its responsibilities in workforce development with key programs being consolidated within the department. AIDT remains the centerpiece of Alabama’s workforce development efforts. “It’s always nice when rankings come out and people outside of the state recognize the job you’re doing as an organization,” said Deputy Commerce Secretary for Workforce Development and AIDT Director Ed Castile said. “But it really says more about the people of Alabama who go through training and get those advanced skill jobs and make the products that people want. They truly are the best assets we have.” Alabama also ranked No. 6 among the states in the “Education: Tech Skill Leaders” category and No. 9 for “Lowest Industrial Electricity Rates.” Business Facilities has been ranking states annually for 11 years. Alabama Newscenter: Alabama shucks! Oyster means world for Gulf Coast farmers Alabama’s oyster reefs have historically harvested an average of one million pounds of oysters per year and have made it one of the top oyster producing states in the nation for more than a century. But changes to water temperature, environmental impacts, parasites and other issues have made the reefs unpredictable and, at times, unproductive. Oyster farming – with the help of the Auburn University Shellfish Laboratory – has emerged as a more controlled way of continuing Alabama’s oyster producing traditions. This video story put together by Joe York for the Southern Foodways Alliance based at the University of Mississippi’s Center for the Study of Southern Culture talks about how oysters have a strong future through farming in the state. “In 2009, not a single oyster farm operated on the Alabama coast. By 2015, there were eight oyster farming companies, all determined to prove that the world’s best oysters come from this Southern state. Lane Zirlott, of Murder Point Oyster Company, calls it an oyster revolution – one that focuses on presentation as much as taste, and enables hard-working families to make a consistent living on the Alabama waters,” York wrote in the introduction to the video. Officials want to see farming grow alongside increases in reef harvesting to boost oyster production in Alabama to new heights. Birmingham Business Journal: Blue Bell resumes ice cream production at Sylacauga plant Blue Bell Creameries on Wednesday confirmed that production has officially resumed at its Sylacauga facility as the company looks to move forward following a listeria scare that halted work across its footprint. The ice cream products are currently being added to the company’s inventory, but no date has been given as to when products will return to store shelves, according to a report from Fox 6. The company began trial runs at its Sylacauga plant in July, and over the last month, have continued until production was ready to return to a normal pace. A spokesman for the Alabama Department of Public Health, which has partnered with the company through the process, said Blue Bell has run tests at the Sylacauga plant and are free to produce and sell ice cream products. Blue Bell in April recalled all of its products after at least 10 people were diagnosed with listeria. Three of those infected died, according to the Centers for Disease Control and Prevention. The company closed its four locations in Alabama, Oklahoma and Texas for cleaning, in addition to saying the Blue Bell staff at all facilities would undergo training to emphasize aggressive cleaning methods. Blue Bell in May laid off more than a third of its workforce following the closing of the plants and furloughed an additional 1,400 workers. Birmingham Business Journal: Alabama among worst states for student loan debt A new report claims more than 11 percent of all student debt is currently in default – and Alabama is faring much worse than other states. That’s according to a new report by WalletHub, which ranked Alabama 44th overall on the list of the best states for student loan debt. The study took several factors into account, including average debt, student loan debt as a percentage of income, unemployment rate and percentage of student loans in default. The state scored the worst in unemployment for adults aged 25-34, coming in at 50th. Alabama ranked 44th for the percent of student loans in default and 39th for average student debt. WalletHub’s report said the best states were Utah (No. 1), Wyoming (No. 2) and North Dakota (No. 3). Yellowhammer News: High-tech European space company to launch manufacturing operation in Alabama Switzerland-based RUAG announced Friday that it will launch an Alabama manufacturing operation after forming a strategic partnership with United Launch Alliance, which produces rockets at a factory in Decatur. RUAG, one of Europe’s leading suppliers of products for the space industry, said the new Alabama

Alabama business roundup: Headlines from across the state

Here’s a roundup of some of the weekend’s top business headlines from across the state: AL.com: Alabama businesses hope to nip beverage tax in the bud The head of Buffalo Rock Co. said a soft drink tax proposed to help fix the state’s General Fund budget shortfall would hurt the state’s economy. “It’s a job killer and would have an enormous trickle effect throughout our economy,” said Matthew Dent, president and chief operating officer of the Birmingham-based company, which employs 2,100 people. Buffalo Rock is one of about 300 partners signed up for the Stop the Alabama Beverage Tax campaign. They include bottling companies, retailers, restaurants, trade associations, city governments, schools and others. They launched a website, Facebook page and advertisements. Dent said the main goal is to tell people what the group believes would be the harm done by such a new tax. Legislators have not introduced a soft drink tax bill, but Gov. Robert Bentley included it in his proclamation calling the special session. It would be the biggest component in the governor’s proposed $302 million tax increase package. It’s not a first option for the governor, who said he prefers an alternative — repeal of the state income tax deduction for Social Security taxes paid. Either proposal would raise about $180 million annually. Acting Finance Director Bill Newton said the soft drink tax estimate is based on a tax of five cents per 12 ounces. That would add 60 cents to the cost of a 12-pack and about 28 cents to the cost of a 2-liter bottle. Soft drinks are now taxed at the general sales tax rate — a 4 percent state tax plus local taxes. Aside from the added cost of a new tax, Dent said any tax that singles out one industry is the wrong approach. “Buffalo Rock would support a broad-based tax that’s fair and equitable that everybody participates in,” Dent said. The Legislature is in recess and will resume the special session on Aug. 3. Some legislators have indicated that the soft drink tax and the repeal of the Social Security deduction don’t have much support. The governor has also proposed raising the maximum business privilege tax, raising the tax on tobacco products, adding a new tax on vapor cigarettes and some budget reforms. House Speaker Mike Hubbard, R-Auburn, said it was too early to say which proposals have a chance to pass. “I’m just not in a position to talk about which ones we’d move forward with,” Hubbard said. “We have discussed all of them at length. In the legislative process, it’s all about putting together a package that you can get the votes for.” Legislators have been meeting in groups during their recess and are trying to find some consensus. Bentley vetoed the budget legislators passed in June. It would have cut General Fund spending 11 percent, to $1.6 billion. Bentley has proposed a plan that would spend $1.9 billion from the General Fund. Officials say that a budget without new revenue would force cuts in services to the poor and the mentally ill, law enforcement, prisons, courts and other areas. “It’s a hard decision legislators have,” said Virginia Bear, executive director of the Alabama Beverage Association, a bottlers’ organization. “We would hope the solution is fair and broad-based and equitable. A beverage tax is certainly not because it singles out one industry.” AL.com: REEL wins Airbus contract, plans first U.S.-based subsidiary at Mobile Aeroplex at Brookley France-based REEL Group is establishing its first U.S. facility with 4,500-square-feet of office, warehouse, and workshop space at Mobile Aeroplex at Brookley. Monday’s announcement is in direct response to REEL Service Division being awarded the jigs and tools maintenance service provider contract for the Airbus U.S. Manufacturing Facility, also located at Brookley. The newly formed subsidiary, dubbed REEL USA Corp., is expected to create more than 20 full-time positions, and its lease with Brookley allows for expansion as needed. “(REEL’s) expertise in the area of advanced manufacturing processes is a great asset to the growing manufacturing sector in Mobile County and, in particular, to the Airbus U.S. Manufacturing facility at the Mobile Aeroplex at Brookley. We look forward to a partnership with the company and are proud to be the chosen location of REEL’s first U.S. work site,” Mobile County Commission President Jerry Carl said in a prepared statement. Financial terms of the deal were not disclosed. Roger Wehner, executive director of the Mobile Airport Authority, said although Airbus’ state-of-the-art A320 final assembly hangar is “expertly designed,” the actual task of aircraft assembly “will happen via the hands of well-trained employees.” “The jigs and tools elevate them and facilitate the task, and REEL will help them maintain that critical foundation. While REEL will support the Airbus production facility, it also constitutes a critical capability set in our constant evolution, and we know this differentiates us from other communities,” Wehner said. Toulouse, France-based Airbus will launch production this month at its first A320 final assembly line on U.S. soil at Brookley in the company’s ability to efficiently fill the mounting backlog for the popular single-aisle aircraft. The $600 million facility is expected to deliver its first Mobile-assembled aircraft to JetBlue in the second quarter of 2016 and employ about 1,000 people when it reaches full annual production of 40 to 50 aircraft by 2018. Meanwhile, REEL Service Division provides maintenance; installation and commissioning; studies, consulting and expertise; improvements, modifications and compliance; assistance and training. REEL Group member COH, founded in 1969 and located in Quebec, Canada, will also support REEL USA Corp. in its development. For more than seven decades, REEL has specialized in custom-made handling systems for sectors where safety and reliability are major concerns, including nuclear energy, aluminum production, aeronautics, defense and offshore systems. The conglomerate has exhibited particular expertise in the aviation sector by providing and maintaining aircraft docking systems, telescopic platforms and engine-handling systems. Mobile Mayor Sandy Stimpson called REEL a “world-class company” and a “great addition to our community as we seek to expand our advanced manufacturing capability.” “I particularly want to commend the Mobile