REHAU holds event to celebrate latest expansion in Cullman

On Tuesday, the Cullman REHAU plant hosted a Roofing Ceremony/Richtfest to celebrate its latest expansion. The $12.8 million expansion will allow REHAU to increase production at its Cullman plant even more. Andrew Frohne is a senior executive with REHAU. “Thank you for coming to our milestone event,” Frohne said. “It was a pleasure having you here. We hope you have a good impression of our project and are looking forward to showing you the progress at the next big milestone.” Economic Developer Dr. Nicole Jones told Alabama Today, “REHAU, which now employs almost 800 at the Cullman plant, was the first Tier 1 supplier to serve Mercedes when it came to Alabama nearly three decades ago. Thank you, REHAU, for investing in our communities. “ The German word “Richtfest” translates to ‘roofing ceremony’ or ‘build celebration.’ In German tradition, building owners or homeowners host a “Richtfest” when the final roof beam is applied. The Mercedes Benz supplier opened its Cullman plant in 1996 with 30 employees. The company has had several expansions since then and now employs over 800 people. A PEXa pipe plant for heating and plumbing applications was opened in 2007, and a technical center was added in 2015. According to the Alabama Department of Commerce, the largest single permit issued in Alabama in the second week of July 2023 was a $12.8 million permit at the Cullman Rehau Automotive plant. “REHAU has played a vital role in the success of Alabama’s automotive industry for 25 years, and it’s great to see the company expand its operation in Cullman,” Governor Kay Ivey said when the expansion was first announced in 2022. “This expansion and the 125 new jobs it will create will be vital to Mercedes-Benz’s growth right here in Sweet Home Alabama.” The current facility is about 1 million square feet. The independent family-owned company was founded in Rehau, Germany. Today, REHAU has 21,500 employees in more than 190 locations worldwide. Dale Greer is the director of the Cullman Economic Development Agency. Greer said, “REHAU’s growth in Cullman is a tribute to both the company and the Cullman community.” The Mercedes Tuscaloosa plant was the company’s first major passenger car production facility outside Germany. REHAU followed Mercedes to Alabama. Since then, several other automobile makers have moved production facilities to Alabama. Both Mercedes and REHAU have expanded over the years. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

CFD Research expands their facility in Hollywood, Alabama

Last week, CFD Research Corporation held a groundbreaking ceremony for an additional facility at its Engineering Test Center in Hollywood, Alabama. The company said that the new 19,000-square-foot building will support work for ongoing contracts with the Army Space and Missile Defense Command (SMDC), the Air Force Arnold Engineering Development Complex (AEDC), and other customers. Sameer Singhal is the President and CEO of CFD Research. “Thank you to the town of Hollywood and Jackson County for welcoming us so graciously and celebrating this groundbreaking event, and thank you to the Alabama Department of Commerce for its support,” said President Singhal. The location and proximity to our other facilities has been an ideal solution and will enable us to work more efficiently and economically.” Economic developer Dr. Nicole Jones told Alabama Today, “CFD Research has grown exponentially in two years.” “The company offers highly-skilled career opportunities in manufacturing, system integration, and test and evaluation services,” Jones said. “CFD Research’s 19,000 square foot facility in Jackson County further enhances north Alabama’s role in supporting the Department of Defense and national security.” Greg Canfield is the Secretary of the Alabama Department of Commerce. “CFD Research specializes in delivering next-level technologies, services, and products that keep us all safe, and this expansion project at its Hollywood site will help the company achieve new milestones in that critical mission,” said Secretary Canfield. The building will provide more than 28 additional offices, a second-high bay, larger conference room space, and closed areas for classified meetings. This facility will expand the team’s capability to provide services, perform technology development, and enable increased test capacity. In August 2021, CFD Research opened its 13,125-square-foot test and evaluation facility on 10.4 acres in Jackson County Industrial Park in Hollywood, AL. In November of 2022, CFD Research added another 63 acres of property to the facility and an additional test stand that is four times larger than CFD Research’s previous capability to expand the company’s manufacturing, system integration, and test and evaluation services. CFD Research started with just four employees at the Testing Center when it opened in 2021. It has grown to 22 employees presently. CFB anticipates surpassing over 40 employees in the near future. US Congressman Dale Strong (R-AL05) headlined the ceremony. “It was a pleasure visiting Jackson County this week,” Rep. Strong said. “I started the day celebrating CFD Research’s expansion at the industrial park in Hollywood.” State Senator Steve Livingston, Scottsboro Mayor Jim McCamy, and Nathan Lee, President of the Jackson County Economic Development Authority, were also in attendance. CFD Research Corporation specializes in engineering simulations, advanced prototypes, and innovative designs for aerospace, defense, life sciences, materials, energy, and other industries. CFD Research uses its software and experimental capabilities to develop new hardware concepts, innovative designs, and superior solutions for its customers with lower risk, reduced costs, and less time. CFD Research has grown steadily and profitably every year since its inception in 1987. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Wallace State announces millions in new funding

Wallace State Community College last week celebrated the grand opening of the $8.8 million Center of Welding Technology and Innovation Center. At the ribbon-cutting ceremony, Wallace State President Dr. Vicki Karolewics announced new plans for almost $49 million in capital investments to build or renovate three buildings on the Hanceville campus. “Our theme for today is rightfully entitled Building the Workforce because as one of Alabama’s most ambitious colleges, that is our mission — to build the workforce of the future,” Karolewics said. “We began incubating entrepreneurs over a decade ago, and we are proud of the hundreds of jobs created by ZeroRPM, Sequence Health, and DB Technologies in this community,” Karolewics continued. “This Innovation Center project is projected to create ninety-eight jobs and $25 million in revenue for our area within the first eight years.” “It’s an honor to be a part of this history-making day,” said Alabama Governor Kay Ivey. “We are literally standing on ground zero in the campaign to equip new Alabama workers and those who are choosing to reenter the workforce with skills to succeed.” While the state has record-low unemployment, Gov. Ivey has become increasingly troubled by the state’s ranking nationally as a state with one of the lowest workforce participation rates. “Providing pathways for them to join the workforce is a major priority,” Ivey said. “Alabama’s 24 community colleges are on the front lines in delivering the training many of these workers need to get to work.” The 30,000-square-foot Center for Welding Technology and Innovation is the largest training center in the Southeast. The new Welding Technology Center has seven robotic welding stations; nine virtual welding simulators; 81 welding booths; 20 grinding booths; a fabrication area with two welders, a plasma CNC table, and pipe welding equipment; and three state-of-the-art classrooms with built-in cameras, microphones, and speakers to allow hosting online classes. Skilled, certified welders are in high demand by Alabama industry. Economic developer Dr. Nicole Jones told Alabama Today, “The $48 million capital investment will allow Wallace State Community College to provide multiple trade credentials and certifications for in-demand automotive, electrical, welding, and STEM careers. Whether someone is a traditional postsecondary student or desires a career change later in life, Wallace State Community College offers opportunities to excel.“ Karolewics said that $4.2 million will be used for the expansion and renovation of the Machine Tool Technology building. Wallace State has partnered with HAAS Automation, which has been critical in enabling Wallace State to produce the most advanced machinists in this region. Another building project is a $9.6 million Facility for Automotive Technology to accommodate the transformation of the automotive industry to electric and autonomous vehicles. Dr. Karolewics said Wallace State has partnered with Mercedes Benz, Nissan North America, Cullman Electric Cooperative, and the Tennessee Valley Authority on this project. Benton Nissan donated a Nissan Leaf to the Advanced Automotive Service Technology program, as Mercedes-Benz has done in the past. This is the college’s first electric vehicle for training. The Cooperative and TVA have committed $44,000 for two electric vehicle chargers, with another planned in the future. The largest building project is a $35 million STEM Gateway Building, which will house all the college’s first-year students in mathematics, English, humanities, speech, and chemistry, as well as the Culinary Arts program, a digital learning center, and a tutoring center. Dr. Jones said, “Education and training and stable employment help break the cycle of generational poverty, and when Alabamians are working, we all benefit.” To connect with the author of this story or to comment, email brandonmreporter@gmail.com

Trendco investing $43 million in Macon County

On Thursday, Trendco USA announced plans to invest $43 million to launch a nitrile medical glove manufacturing operation in the new Regional East Alabama Logistics (REAL) Park in Macon County. The company plans to create 292 jobs over five years at its new facility. South Carolina-based Trendco also considered sites in Georgia and the Carolinas for the project. Darryl Hunter is the CEO of Trendco USA. “We are very excited about our move to Alabama and look forward to building our PPE manufacturing facility in Tuskegee,” said Hunter. “We believe the people of Tuskegee and the surrounding communities will play a vital role in our success in the medical technology sector.” Trendco is an early-stage company that has been producing medical-grade examination gloves in Louisiana through a partnership with another company. The company plans up to install as many as 10 glove production lines at the REAL Park location in Tuskegee. Once these lines are established, the company plans to expand production into masks and gowns, ensuring a reliable domestic source for these important PPE items to mitigate potential supply chain disruptions. The recent COVID-19 global pandemic and the global shortages in PPE that resulted “Trendco decided to locate its manufacturing facility in Tuskegee after considering many locations in other states, and I know that the company made the right choice by selecting Macon County for its investment project,” said Alabama Governor Kay Ivey. “I look forward to seeing the company grow and thrive in Sweet Home Alabama.” Economic developer Dr. Nicole Jones told Alabama Today, “When a company grows rapidly and needs to choose a new location to manufacture its product or provide services, having a building ‘ready’ is a tremendous advantage in the site selection process because it reduces or eliminates many of the unknowns associated with construction timelines. The initial 168,000 square foot, Class A warehouse, and manufacturing spec building (Building 100), part of a multi-phase project, helped make the site selection process more efficient. Trendco has signed an agreement to lease over 100,000 square feet of space in Building 100 in REAL Park. There the company will initially set up a distribution operation as it ramps up its new glove manufacturing lines. Trendco is seen as a catalyst project for the new 700-acre Class A industrial park located off Exit 42 on I-85. “REAL Park, located near the interstate, has a capacity to eventually expand into 6 million square feet. As qualified companies such as Trendco USA lease within the park, the long-term economic benefits for Macon County and our entire state will be profound,” Jones explained. Justin Patwin is a principal at Farpoint Development – the master developer leading the project. “REAL Park will eventually offer a combined 6.2 million square feet of space when the project’s three phases are completed in five to seven years,” Patwin said. “We and our partners at OPAL are very excited to welcome Trendco to REAL Park. They are making a significant commitment to Macon County and the State of Alabama to bring many new jobs to the community — we feel this is an incredible start to the overall economic impact REAL Park will have in the region.” Alex Flachsbart is the founder and CEO of Opportunity Alabama (OPAL) and the principal of the Opal Fund – the lead investor in Building 100. “We created The OPAL Fund to invest in catalytic projects that could produce compelling returns for both investors and communities across Alabama, and Building 100 is the perfect example of that thesis in action,” explained CEO Flachsbart. Greg Canfield is the Secretary of the Alabama Department of Commerce. “The park is perfectly positioned to capitalize on the growth of the I-85 corridor, and I believe other companies will be putting down roots there in the near future,” Canfield said. “We believe the people of Tuskegee and the surrounding communities will play a vital role in our success in the medical technology sector.” The Macon County Commission, Macon County Economic Development Authority, and other local institutions are supporting the Trendco project with utility upgrades and industrial access roads at the site worth $1.1 million, and other in-kind services. Joe Turnham is the director of the Macon County Economic Development Authority. “Trendco USA also chose our community, in part because of our community’s rich history and our local stakeholders’ spirit of enthusiastic partnership in assuring their company’s success,” Turnham said. AIDT, the state’s primary workforce development agency, is also providing services to advance the project. Brenda Tuck is the Rural Development Manager at the Alabama Department of Commerce. “We’re committed to seeing rural Alabama fully realize its growth potential, and this project headed to Tuskegee is another illustration of how we’re making progress on that front,” Tuck said. “Opportunities are flourishing in the state’s rural communities, and the business world is paying attention.” “Trendco USA is the only minority-owned medical glove and PPE manufacturer in America and is one of the few companies offering ‘Made in the USA’ medical glove products,” Turnham said. “Now, these gloves will also carry a ‘Made in Tuskegee’ label.” To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

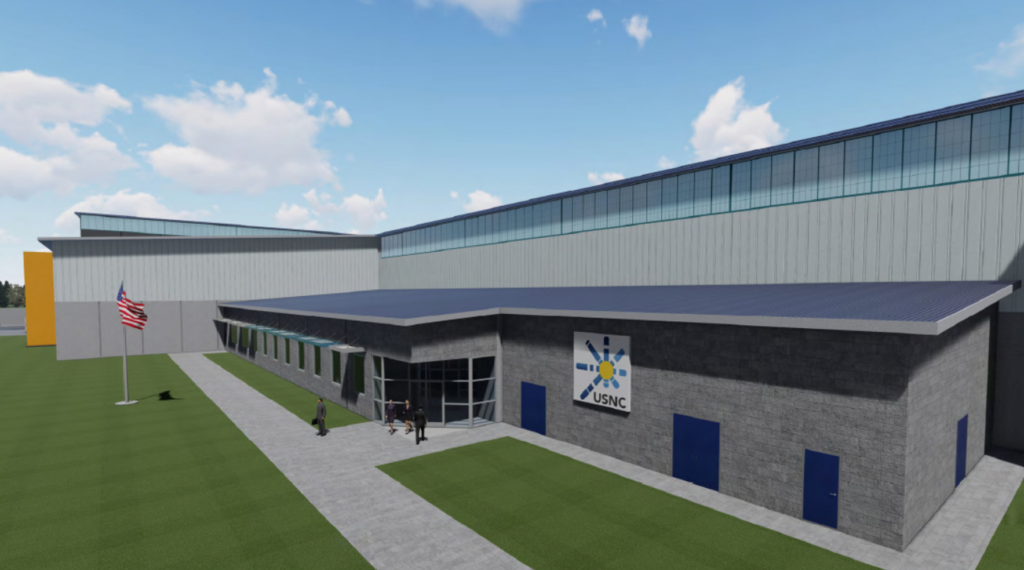

Governor announces Ultra Safe Nuclear Corp. plans $232 million micro-reactor assembly plant in Gadsden

Governor Kay Ivey announced on Wednesday that Ultra Safe Nuclear Corporation (USNC), a Seattle-based company, plans to invest $232 million to locate a facility in Gadsden to produce its industry-leading Micro-Modular Reactor. The highly automated MMR Assembly Plant (MAP) will manufacture, assemble, test, and inspect the non-radiological modules needed to construct its advanced microreactors. No radioactive material will be used or stored at the company’s new Alabama facility. USNC says the Gadsden plant will be the nation’s first commercial-scale microreactor production facility. When operational, MAP will employ 250 professional and technical workers. “Alabama is home to an impressive array of highly innovative companies, so our state is an ideal place for Ultra Safe Nuclear Corp.’s new advanced microreactor assembly plant,” said Gov. Ivey. “This unique facility will benefit the Gadsden community through a significant investment and the creation of good jobs, while also reinforcing Alabama’s reputation for cutting-edge manufacturing operations.” It’s no secret Alabama has a knack for recruiting cutting-edge manufacturing operations. Today, I announced @UltraSafeNuke plans to invest $232 million to locate a unique facility in Gadsden, creating 250 good jobs for Alabamians! #alpoliticshttps://t.co/gTuLi8xGIY — Governor Kay Ivey (@GovernorKayIvey) June 21, 2023 Dan Stout is USNC’s Chief Nuclear Officer. “We appreciate the interest and support for this effort from the City of Gadsden, Etowah County, the Alabama Department of Commerce, and so many others up to and including Governor Ivey and her talented team,” said Stout. “We especially appreciate the guidance and efforts of April Gray at the Department of Commerce and David Hooks of the Gadsden-Etowah Industrial Development Authority in making this project a reality.” USNC said the decision to locate in Gadsden resulted from a year-long search spanning 16 states and hundreds of potential sites. Primary factors evaluated included site suitability and infrastructure, skilled workforce availability, and overall project economics. Economic developer Dr. Nicole Jones told Alabama Today, “Companies consider many factors in the site selection process. A business-friendly climate that includes a quality and skilled workforce, infrastructure, low taxes, competitive incentives, and an excellent quality of life facilitates an environment conducive for business. The direct and indirect jobs created as a result of Ultra Safe Nuclear Corp.’s 578,000 square foot microreactor assembly plant will benefit Gadsden and the entire state of Alabama.” USNC and the State of Alabama formalized the deal through a project agreement executed by Gov. Ivey and Stout. The agreement was announced by Stout at the 10th Advanced Reactors Summit and Technology Trailblazers Showcase. The 578,000-square-foot factory will feature state-of-the-art advanced manufacturing processes and equipment and will be capable of producing up to 10 complete MMR nuclear units per year. Ted Coulter is the plant director for the MMR factory at USNC. “We are attracted to Gadsden by their skilled workforce and the outstanding training programs and support they are bringing to the table,” said Director Coulter. “In Gadsden, I have confidence we can hire local talent and operate with both safety and efficiency. We are looking forward to becoming a member of the community.” Construction is slated to begin in 2024, with the facility operational in 2027. “This is a game-changer for Gadsden,” said Gadsden Mayor Craig Ford. “Ultra Safe Nuclear Corp.’s selection of Gadsden proves what I’ve known all my life about the unmatched grit and capability of our workforce.” To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Austal awarded contract for another Navy towing, salvage, and rescue ship

Austal USA has been awarded a contract for an additional Towing, Salvage, and Rescue ship (T-ATS 15) for the U.S. Navy. With the award, the company is now under contract for five T-ATS, having received awards for T-ATS 13 and 14 in July 2022 and T-ATS 11 and 12 in October 2021. Paddy Gregg is Austal Limited Chief Executive Officer. Gregg said that the contract award again highlights Austal USA’s growing steel shipbuilding capability following the start of construction on T-ATS 11 and 12 and, more recently, the Auxiliary Floating Dock Medium for the United States Navy. “Austal USA’s steel shipbuilding capabilities and capacity continues to impress, with three steel vessels now underway in Mobile, Alabama, in addition to the multiple aluminum vessels and component projects also under construction,” CEO Gregg said. “In addition to the LCS, EPF, and T-ATS programs, construction has just commenced on the steel Auxiliary Floating Dock Medium (AFDM), which will further demonstrate Austal USA’s capabilities and capacity to deliver large steel vessels for the United States Navy and United States Coast Guard.” “The Austal USA team are also delivering submarine modules for the Virginia-class submarines and aircraft elevators for the Gerald R. Ford-class aircraft carriers, so they are without doubt making a significant contribution to the United States’ defense industrial base,” Gregg added. T-ATS is an ocean-going tug, salvage, and rescue ship designed to support the United States Navy’s fleet operations, with a multi-mission common hull platform capable of towing heavy ships. The ships can support a variety of missions, including oil spill response, humanitarian assistance, search and rescue, and surveillance. Economic developer Dr. Nicole Jones told Alabama Today, “Members of Austal USA’s quality and skilled workforce are equipped to handle complex tasks. The company, which started in Mobile in 1999 with 100 employees on a 14-acre campus, has grown to over 3,000 employees and 165 acres. At their state-of-the-art enclosed steel production facility in Mobile, Austal USA integrates lean manufacturing, modular construction, and moving assembly lines into its proven shipbuilding processes. The contract award translates into local jobs and reaffirms Austal’s longstanding commitment to the State of Alabama and their role in national security.” Construction is due to commence on T-ATS 13 and 14 in the second half of this year. T-ATS 15 is scheduled to commence construction in the first half of 2024, with delivery planned in late 2027. Austal USA utilizes its proven ship manufacturing processes and innovative methods that incorporate lean manufacturing principles, modular construction, and moving assembly lines, all housed under the company’s state-of-the-art enclosed steel production facility in Mobile, Alabama. In addition to T-ATS, Austal USA is currently constructing the United States Navy’s Independence-variant Littoral Combat Ships and Spearhead-class Expeditionary Fast Transport ships and has commenced construction of a 211-meter steel Auxiliary Floating Drydock (Medium). In May, Austal USA was awarded a contract for the detail, design, and construction of up to 7 steel T-AGOS Ocean Surveillance Ships worth up to US$3.2 billion, and in 2022, the company was awarded a contract for up to 11 steel Offshore Patrol Cutters for the United States Coast Guard, worth up to U.S. $3.3 billion. Austal is a major employer in Southwest Alabama. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Alabama wins Silver Shovel Award for 2022 economic development successes

Last week the State of Alabama was awarded a Silver Shovel Award. Alabama Governor Kay Ivey announced that Area Development, a national business publication, has selected Alabama for its Silver Shovel Award. This is in recognition of the state’s economic development successes during 2022. “The Silver Shovel Award is yet another testament to Alabama’s strong pro-business environment and to the talented workers that help companies from around the world grow and thrive,” said Gov. Ivey. “This honor also demonstrates that our efforts to create good jobs and spark economic growth are producing results in Sweet Home Alabama.” 👏: Once again, Alabama has claimed a Silver Shovel Award from @AreaDevelopment for our 2022 economic success. Just last year, companies made $10.1 billion in capital investment in Alabama, shattering our previous record! ⬇️ #alpolitics (1/2) — Governor Kay Ivey (@GovernorKayIvey) June 7, 2023 Area Development also cited Atlanta-based Novelis’s plan to invest more than $2.5 billion to build a new low-carbon recycling and rolling plant in Baldwin County as one of its ‘Projects of the Year.’ The project in Bay Minette is expected to create 1,000 jobs. Economic Developer Dr. Nicole Jones told Alabama Today, “Area Development Magazine has been a leading publication in our industry for over five decades. The selection of Alabama for a Silver Shovel Award is a testament to teamwork; the public and private sectors have collaborated and created an environment conducive to business. Since being elevated to the Governor’s office in 2017 after then-Gov. Robert Bentley’s resignation, Ivey has put a strong emphasis on economic development and competing for new capital investment. Since becoming Governor, Ivey has announced new capital projects of $41 billion, creating 80,000 new jobs for Alabamians and creating the lowest unemployment numbers in the history of the state along the way. Ivey’s economic development team is led by Greg Canfield – who is the Secretary of the Alabama Department of Commerce. “Last year was a remarkable one for Alabama’s economic development team,” said Sec. Canfield. “Not only did these professionals secure high-impact growth projects for the state during 2022, but they also managed to set records while doing it. Their efforts are creating exciting new career opportunities for Alabama citizens and enhanced growth possibilities for communities across the state,” he added. “And we’re not slowing down.” In 2022 the state compiled $10.1 billion in announcements of companies building or expanding facilities in the state. This shattered the old record of $8.1 billion set in 2018. The Silver Shovel Award recognized these record results for Alabama’s economic development team. This $10.1 billion in capital investment last year will create over 13,000 jobs across Alabama and stimulate economic growth in both urban and rural areas of the state. “Companies consider many factors in the site selection process, such as a quality and skilled workforce, infrastructure, pro-business policies, community-oriented towns, and school systems, and the proximity to customers and vendors,” Jones explained. “An estimated 13,000 new jobs will result from new facilities and the expansion of existing sites throughout Alabama.” Area Development magazine’s annual Shovel Awards recognize state economic development agencies that drive significant job creation through innovative policies, infrastructure improvements, processes, and promotions that attract new employers and investments in new and expanded facilities. The awards are presented annually to states that have achieved significant success in terms of job creation and economic impact. Factors that go into this calculation include the number of high-valued added jobs per capita, amount of investment, number of new facilities, and industry diversity of the submitted projects. Alabama qualified for a Silver Shovel award in the 4- to 6-million population category. Other winners in the category were South Carolina and Wisconsin. 2022 was marked nationally with large-scale projects related to electric vehicles. Area Development singled out two projects in Alabama: Hyundai’s $300 million investment to launch EV production at its Montgomery plant and Hyundai Mobis’ $205 million battery module plant nearby. Area Development also highlighted growth plans in Alabama by Airbus, First Solar, United Launch Alliance, Manna Beverages & Ventures, and Diego. This is far from the first time the magazine has honored Alabama with Shovel Awards. It received Gold Shovel Awards in 2006, 2013, 2019, and 2021, and Silver Shovel Awards for 2007–2012, 2014–2018, and now in 2022. Last September, Area Development reported that Alabama ranked Number 6 in its annual “Best States for Doing Business” survey, containing a sustained run for the state in that list’s Top 10. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Southwire to expand its manufacturing plant in Florence creating 120 jobs

Southwire, one of North America’s largest wire and cable producers, announced plans on Friday for an expansion of its manufacturing campus in Florence. The effort is expected to increase production capacity by 30% and create approximately 120 jobs. “At Southwire, we’re making a multi-year investment of more than a billion dollars to integrate newer and better equipment, systems, and technology into our operations to increase efficiency,” said Southwire President and CEO Rich Stinson. Stinson said the expansion will, “Enhance competitiveness and ensure the operational capability and capacity to support our strategic growth. The Florence expansion is a testament to those efforts.” Economic developer Dr. Nicole Jones told Alabama Today, “Southwire’s commitment to long-term growth is evident with its latest expansion announcement. The Shoals location investment, which focuses on commercial and residential building wire production, will add 120 jobs to its current total of 625+. A productive, welcoming environment in which companies choose to re-invest in existing buildings, employees, and the local community is a testament to partnerships between the public and private sector and a framework conducive for business.” Southwire also has a facility in Heflin and an Alabama statewide workforce exceeding 625. Greg Canfield is the Secretary of the Alabama Department of Commerce. “Southwire’s investment project will create good-paying jobs in Florence while also enhancing the facility’s competitiveness and solidifying its future in the community,” said Sec. Canfield. “Southwire is a world-class company and a great corporate partner at the state and local level. We’re thrilled to see them grow and thrive in the Shoals area.” The Southwire Florence Plant was acquired from Essex in 2006 to support the company’s production of commercial and residential building wire. The 300,000-square-foot campus has grown over time, and this expansion will include approximately 340,000 square feet of added space for new equipment. Norman Adkins is the president of Wire and Cable and the COO. “Southwire is committed to remain generationally sustainable for the next 100 years and beyond and be an employer of choice,” said President Adkins. “We look forward to the growth opportunities that this expansion will bring to our company.” The expansion not only increases operating space and new equipment but will include renovations to the existing building to enhance the team member experience, including locker rooms, training space, and an outdoor picnic and activity area. “This investment will allow us to better service our customers safely and efficiently, and the Florence team and I are very excited about the expansion and what it means for the future,” said Brian Davis, plant manager. “This expansion speaks volumes about the dedication, hard work, and commitment of our team members, and we look forward to the opportunities that this expansion will bring.” The investments and upgrades will effectively streamline Southwire’s commercial and residential building wire efforts, complement existing products and emphasize the facility’s culture and labor pool. Construction at the Florence campus is expected to begin this quarter and should be completed in 2025. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Gov. Kay Ivey awards six Alabama companies with Trade Excellence

On Wednesday, Alabama Governor Kay Ivey hosted the Governor’s Trade Excellence Awards Ceremony. During the event, Governor Ivey signed a proclamation proclaiming May as World Trade Month. This year’s ceremony recognized six of Alabama’s top international trade exporters and finest trade companies, as well as the 2023 Trade Advocate of the Year. “I recognized @TuskegeeUniv and six Alabama companies for their trade success in the global market,” Gov. Ivey said on Twitter. “Their economic activities ranged from automotive manufacturing to food production.” The six exporters honored in the Governor’s Trade Excellence Awards were: · Adah International LLC · Bud’s Best Cookies · Canfor Southern Pine · Hyundai Motor Manufacturing Alabama · ICONN Orthopedics · Pinnacle Solutions, Inc. “Their work has sparked record-breaking economic growth across the state,” Ivey stated. “Thanks to tremendous levels of innovation, craftsmanship, and ingenuity, Alabama’s talented workers turn out products that are in demand around the world,” Governor Ivey said. “These products really elevate the ‘Made in Alabama’ brand and transmit the message internationally that top-quality goods come from our state.” Governor Ivey presented Tuskegee University with a 2023 Governor’s Trade Excellence Award for extraordinary results in international initiatives that include partnerships with dozens of overseas universities and hosting students from more than 20 countries in recent years. Economic developer Dr. Nicole Jones told Alabama Today, “Alabama has a plethora of international trade partners that exemplify the Made in Alabama brand. The Governor’s Trade Excellence Awards gives outstanding organizations well-deserved recognition for their contributions to our state’s success in global markets. Considering the myriad of global disruption that has dominated worldwide news in recent years, it is impressive that Alabama maintained $25.5 billion in exports in 2023. Other countries have demonstrated a continued need for made-in-Alabama goods, especially in the industries of transportation, aerospace, chemicals, minerals, and paper products.” Greg Canfield is the Secretary of the Alabama Department of Commerce. “Exporting is a driving force in Alabama’s economy, providing benefits here at home that include new jobs and investments,” Sec. Canfield said. “The vision of our companies to be international leaders in their respective fields is most impressive, and we look forward to seeing their continued success in overseas markets.” Christina Stimpson is the Director of Commerce’s Office of International Trade. “We are proud to have worked with all the companies represented today and to have assisted them in identifying international opportunities,” Stimpson said. “The communities where they are located are fortunate to have them because, through exporting, they’re diversifying the economy, growing their production, and creating and sustaining jobs.” Alabama exports surged to a record $25.5 billion in 2022. The Department of Commerce’s Office of International Trade offers resources to assist Alabama companies enter new overseas markets. The Office uses its frequent trade and business development missions, training, foreign-market information, and international contacts to further Alabama companies’ international presence. “Economic development is a continuous process of cultivating relationships, investing in human capital, and working with communities to find their hidden talent within,” Jones explained. “Governor Ivey, the Alabama Department of Commerce, and leaders within the public and private sector work every day to make Alabama a place where a myriad of industries can grow and prosper.” To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Vertex Energy has ribbon cutting on new renewable diesel facility

Gov. Kay Ivey was on hand for the ribbon-cutting ceremony of Vertex Energy’s first renewable diesel facility. Vertex Energy is one of the largest processors of used motor oil in the U.S. Gulf Coast. This $115 million expansion project will be Alabama’s first renewable diesel facility. Gov. Ivey said on Twitter, “I welcomed VertexEnergyInc’s Renewable Diesel Unit to Alabama today! This facility is a major milestone for our state, providing 200+ high-paying jobs, work for our farmers and low-carbon fuel products. Truly, Vertex’s Alabama-presence will be felt across the nation.” The project will create over 200 new jobs in Mobile County. The Governor was joined by Vertex Founder and President Ben Cowart, Refinery General Manager Wes Mock, Vertex Site Project Manager Daniel Hill, County Commissioner Merceria Ludgood, and Mobile Chamber President and CEO Bradley Byrne. Vertex Energy, Inc. is a leading specialty refiner and marketer of high-quality refined products. “By sourcing feedstock locally within our own state, Vertex fosters economic growth opportunities from farm-to-facility and offers low-carbon fuel products that contribute to a cleaner environment, not only here in our beautiful Alabama, but across the nations where these products are sold,” Ivey said. In 2022, Vertex acquired a conventional fuels refinery from Shell PLC The company immediately launched a $115 million conversion project. The primary aim of this project was to convert a standalone unit within the refinery to facilitate the production of renewable diesel, a cleaner and more sustainable alternative to petroleum diesel fuel. Economic developer Dr. Nicole Jones told Alabama Today, “Vertex is an energy transition company focused on the production and distribution of conventional as well as alternative fuels. Vertex’s large refinery in Mobile County positioned the company as a leading supplier of fuels in the Gulf Coast region. As one of the largest processors of used motor oil in the United States, Vertex is a champion of sustainability and cutting-edge alternative energy. The 200 jobs created as a result of their latest expansion is a win for Saraland, Mobile County, and our entire state.“ The newly converted renewable diesel unit is specifically designed to produce renewable diesel fuel, which can be seamlessly integrated as a direct replacement for traditional petroleum diesel. At present, soybean oil serves as the primary feedstock for the production process. However, the facility has been engineered to accommodate the use of other organic waste oils in the future. Soybeans are trading currently at $14.72 a bushel. Soybeans are a primary ingredient in livestock feeds as well as in human feedstuffs – much of it in soybean oil. The company said that the plant provides a new market for Alabama’s soybean farmers. The collaboration between Vertex and these suppliers is expected to help strengthen the local agricultural sector and help foster a stable transition to renewable energy sources. Cowart declared, “We’re not just cutting ribbons; we’re cutting emissions. We’re also carving a new path for this site, this city, and the Great State of Alabama. The opportunity to bring this kind of innovation to my hometown and the state of Alabama is incredibly meaningful. I believe this is just the beginning, as we progress on our commitment to a cleaner environment by creating a sustainable growth path for the energy transition.” Vertex worked closely with local engineering firms and other contractors. The project resulted in an estimated $4 million in local workforce spending and the support of 600 construction jobs, as the team achieved over 450,000 work hours without any OSHA reportable incidents. Vertex’s safety incentive program, which allows Vertex employees and contractors to allocate dollars to Make-A-Wish Alabama for every OSHA injury-free workday completed during the turnaround, reached its target of 12 wishes granted for a total of $120,000. Houston-based Vertex Energy, Inc. (NASDAQ: VTNR), is an energy transition company focused on the production and distribution of conventional and alternative fuels. The refinery in Mobile has an operable refining capacity of 75,000 barrels per day and more than 3.2 million barrels of product storage, positioning it as a leading supplier of fuels in the region. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Unemployment in three of Alabama’s metro areas lowest in the country

Alabama Governor Kay Ivey announced Wednesday that three Alabama metropolitan areas have the lowest unemployment rates in the country for March 2023. Statewide unemployment in March was at a record low of 2.3%. The Birmingham – Hoover metro area led all large cities with an unemployment rate of just 1.8%. This is for cities with a metropolitan area of one million or more. Two other state metro areas, Decatur and Huntsville, were ranked as the lowest in the country of any size at 1.6% and tied with Rapid City, South Dakota. “Alabamians have been finding jobs in record numbers for many months now,” said Governor Ivey. “Therefore, it is not surprising that we are home to the lowest unemployment rates among major metropolitan areas in the nation. Alabama workers are not only trailblazers in aerospace, automotive, and agriculture industries – among others – but we are eager to enhance our quality of life. For some time, we’ve been saying ‘Sweet Home Alabama’ is open for business, and the job numbers continue to bear that out.” The rankings are compiled by the U.S. Department of Labor’s Bureau of Labor Statistics. “These rankings are just more proof of how well Alabama’s economy has recovered since the pandemic and demonstrates the dedication in our communities to offer our families good jobs,” said Labor Secretary Fitzgerald Washington. “To think that three Alabama metros beat out all the other metros in the nation is something to be really proud of, and I certainly hope that we continue this streak of achievements.” Economic developer Dr. Nicole Jones told Alabama Today, “Alabama has available jobs and continues to break unemployment records because the public and private sectors communicate to create an environment conducive for economic growth. Workforce development initiatives created through partnerships between businesses, the Alabama Department of Labor (ADOL), and AIDT help ensure Alabamians are trained well and can fill positions available in a variety of areas.” Alabama’s preliminary seasonally adjusted March unemployment rate of just 2.3% is a new record low, down from February’s rate of 2.5%. “We’re almost a quarter into 2023, and we are already seeing record-breaking success when it comes to Alabama’s economy,” said Gov. Ivey. “We have been enjoying a period of low unemployment, high wages, and high jobs count for some time now, and I believe that even greater economic achievements are on their way. We will not back down on our commitment to continue bringing quality, high-paying jobs to Alabama.” “ADOL Secretary Fitzgerald Washington and his team deserve much credit for this because of their willingness to meet communities where they are at and partner with industry to design education and training programs aimed to increase skills needed to attain employment. When Alabamians are working, we all benefit,” Dr. Jones said. The state experienced growth of 54,100 jobs in the past 12 months, with the most significant gains occurring in the manufacturing sector (+10,400), the professional and business services sector (+8,700), and the private education and health services sector (+7,500), among others. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.

Polaris begins shipping first all electric off road vehicles

Polaris has begun shipping the first fully electric RANGER XP Kinetic off-road vehicles from its Huntsville factory to dealerships. These first production all-electric off-road vehicles have all already been ordered by customers. The company began production of the all-electric off-road vehicles this month. Steve Menneto is the president of Off Road at Polaris. “Since announcing our electrification efforts and partnership with Zero Motorcycles, it has been major milestone moments like today’s announcement that have motivated and driven our team to engineer and deliver category-redefining powersports vehicles,” said President Menneto. “The RANGER XP Kinetic demonstrates the game-changing performance advantages that an electric powertrain can provide, and we look forward to getting these vehicles into the hands of our dealers and consumers across the country.” The all-electric Ranger has proven to be very popular with Polaris customers. The company plans to take additional orders on the RANGER XP Kinetic this summer. Josh Hermes is the Vice president of Electric Vehicles for Off Road at Polaris. “We knew there would be interest for a performance-driven electric RANGER, but selling out two hours after opening our initial order window for the XP Kinetic exceeded our expectations,” said VP Hermes. Polaris is based in Minneapolis and produces off-road vehicles, including all-terrain vehicles, snowmobiles, and side-by-side vehicles. The company opened its 900,000-square-foot facility in Huntsville in 2016. Economic developer Dr. Nicole Jones told Alabama Today, “Polaris has been a partner with the state of Alabama since 2016, and the company can now add electric off-road vehicles to its Made in Alabama portfolio. The Huntsville facility is one of Polaris’ largest manufacturing plants, which makes the Slingshot, the RANGER, and most recently, the RANGER XP Kinetic. Several companies in Alabama are on the cutting edge of research and development of electric vehicle technology, a sustainable alternative to fossil fuels.” Greg Canfield is the Secretary of the Alabama Department of Commerce. “From automobiles and airplanes to ships and rockets, Alabamians build all kinds of complex vehicles,” said Secretary Canfield. “Now we can add all-electric off-road vehicles to the list of world-class products made in Alabama.” Other vehicle manufacturers in Alabama have also begun production of all-electric products. Both Mercedes-Benz and Hyundai are producing all-electric vehicles at their Alabama facilities. Autocar, a maker of specialized trucks, delivered its first EV built in Alabama, a battery-electric terminal tractor, last year. New Flyer of America is making zero-emission buses in Anniston. Mercedes is already producing the all-electric EQS SUV at its Tuscaloosa County plant. The company recently announced plans to build the luxury all-electric Mercedes-Maybach EQS 680 SUV in Tuscaloosa. The new luxury vehicle will have two electric motors that are expected to produce 649 horsepower and be capable of accelerating from zero to 60 mph in 4.1 seconds. The range on the new Maybach is expected to be over 285 miles. The all-electric Polaris comes equipped with an on-dash USB port and a 12-v cargo box power port for customers to charge their phones, tools, and accessories. The quietness of the all-electric Ranger XP Kinetic means that it can quietly get a hunter to his tree stand or hunting blind without tipping off everything with ears within a quarter mile like gas engines. The quiet electric engine will also be less disturbing for farmers and ranchers working around livestock. To connect with the author of this story or to comment, email brandonmreporter@gmail.com.