Meghann Bridgeman announced as next Alabama Film Office director

The Alabama Department of Commerce announced last week the selection of Meghann Bridgeman, president and CEO of Create Birmingham, as the next Director of the Alabama Film Office. With extensive experience in arts and economic development, Bridgeman will lead the state’s efforts to attract, support and promote general entertainment productions across Alabama. Bridgeman brings a wealth of knowledge from her work with Create Birmingham’s Film Birmingham Initiative, where she spearheaded numerous initiatives aimed at fostering creative industries and driving economic growth in the film industry. She has a proven track record of building public-private partnerships and collaborating with entertainment professionals and local communities to create opportunities for growth and innovation. In her new role, Bridgeman will oversee the Alabama Film Office, working to position the state as a premier destination for filmmakers and producers. She will begin her new duties in January 2025. Alabama Commerce Secretary Ellen McNair expressed her confidence in Bridgeman’s leadership and vision for the state’s entertainment industry. “Meghann’s background in creative industries and her passion for economic development make her the perfect fit to lead the Alabama Film Office,” Secretary McNair said. “We are excited about her innovative approach and her commitment to leveraging Alabama’s unique assets to attract more entertainment projects, which will ultimately benefit our local businesses and communities,” she added. The Alabama Film Office, which was established in 1978, has been instrumental in the development of the state’s film and entertainment industry. Over the past several decades, it has attracted a variety of high-profile productions, including films such as Big Fish, 42, and Selma. More recently, Alabama has been the site for a growing number of television productions, documentaries and independent films, which have contributed significantly to local economies through job creation, tourism, and infrastructure development. “In partnership with entertainment industry stakeholders across our state, I look forward to joining the Alabama Department of Commerce as the director of the Alabama Film Office,” Bridgeman said. “The entertainment industry has the power to spark transformational economic growth, and Alabamians should be the beneficiaries of that growth. “I am grateful to Secretary McNair for the opportunity to lead this important effort and excited for the work ahead,” she added. The state’s film incentive program, which includes a competitive rebate structure, has helped to establish Alabama as a compelling destination for production companies. These incentives, along with the state’s diverse locations ranging from picturesque coastlines to historic cities, have made Alabama a go-to option for filmmakers seeking authentic, versatile backdrops. Last year, the industry spent nearly $60 million in Alabama on entertainment productions that included The Rivals of Amziah King, starring Matthew McConaughey and Kurt Russell, and The Shift, featuring Sean Astin. Rebates valued at $16.5 million were extended to productions in 2023, according to data from the Alabama Department of Commerce. Under Bridgeman’s leadership, the Alabama Film Office will continue to build on its success by strengthening partnerships with industry stakeholders, expanding production opportunities, and ensuring that Alabamians benefit from the state’s growing entertainment sector. Future plans could include expanding the office’s traditional focus to encompass additional forms of entertainment, including music productions and video games. The office will also maintain a concentration on workforce development and training, ensuring that Alabama remains competitive in the fast-evolving film and media industries. The Film Office’s longtime director, Kathy Faulk, will remain in charge of the office in the interim. “Kathy’s contributions to the Film Office have been significant over many years, and she has been an untiring champion for expanding Alabama’s presence within the entertainment industry,” Secretary McNair said. “Thanks to her, the Film Office is positioned for exciting new developments in the future.” This story originally appeared on Made in Alabama written by Jerry Underwood. Made in Alabama is a project of the Alabama Department of Commerce.

Alabama bioscience sector poised for growth through major investments

Growth projects valued at almost $200 million are underway in Alabama’s bioscience sector, setting the stage for new research funding and recruitment of scientists for cutting-edge projects. The growth spurt will build on investments announced in 2021 by life science companies in the state that totaled $166 million, according to an estimate by the Alabama Department of Commerce. These projects are creating 574 jobs. In Alabaster, Avanti Polar Lipids, which provides pharmaceutical and diagnostics industry products, is adding 67 jobs through a $16 million expansion launched last year, Commerce data shows. In Huntsville, Discovery Life Sciences is creating 140 jobs. And in Auburn, SiO2 Medical Products – which grabbed headlines by developing high-tech vials for COVID-19 vaccines – continued its fast-paced growth with a $123 million investment to expand production. The project is creating 40 jobs. Expanding the state’s bioscience sector is a strategic priority for the Alabama Department of Commerce, which supports industry growth in various ways, including trade missions to overseas biotech clusters and events. A mission to Nordic Life Sciences Days in Denmark is scheduled for 2023. “We have exceptional strengths in biosciences, including world-class research organizations and a roster of cutting-edge companies, so it’s a natural growth area for the state,” said Greg Canfield, secretary of the Alabama Department of Commerce. “Our goal is to help unleash brainpower and provide a catalyst for innovation within this important economic sector,” he said. While it’s overshadowed by the automotive and aerospace industries, Alabama’s bioscience sector already delivers a major financial impact for the state through activities that include medical research, drug discovery, genomic medicine and medical devices. Alabama is home to 780 bioscience establishments employing almost 18,000 people earning average annual salaries exceeding $67,000, according to an analysis conducted for Bio Alabama, an industry trade group. Biotech foundations During 2022, all three of Alabama’s major research institutions embarked on significant growth projects that will allow them to create new laboratory jobs while positioning them to make high-impact scientific discoveries. Southern Research – a landmark in Alabama’s bioscience sector since its founding in 1941 – is preparing to begin construction on a flagship biotech center in Birmingham. The organization plans extensive renovations on its campus. Coming in 2024, the new biotech center will feature 106,000 square feet of commercial wet labs, A/BSL-3 space and data science facilities. Renovations to 65,000 square feet of facilities include vivarium space and a new clinical diagnostics lab. Southern Research’s biotech center is projected to create 150 jobs, while doubling the organization’s annual economic impact to $300 million. “This is going to be another game-changer for Alabama,” said Gov. Kay Ivey, who approved a $45 million state investment in the biotech center. “We are proud of our investment. It’s going to help Alabamians and help change the world.” Southern Research is investing more than $108 million in the overall project, according to its 2021-2022 annual report. Also in Birmingham, UAB is constructing the Altec/Styslinger Genomic Medicine and Data Sciences Building to advance its leadership in precision medicine, genomic science, and biomedical research. UAB officials said the facility will allow the university to recruit 75 investigators and about 350 support staff to work alongside the talented cadre of researchers. It expects the center to attract an estimated $100 million in additional research funding annually. Total project costs are expected to exceed $78 million, including significant financial support from the state. Construction could be completed in spring 2024, according to UAB. Together, these projects represent groundbreaking initiatives to enhance research capabilities, create jobs, and generate new investment, while propelling Birmingham and Alabama to the forefront of innovation built around discoveries. “Between UAB and Southern Research, we are working to ensure that Birmingham and Alabama become the biotech commercialization center of the Southeast,” said Dr. Ray Watts, president of UAB and chair of the Southern Research board. Unleashing brainpower In Huntsville, the HudsonAlpha Institute for Biotechnology is growing in new and exciting directions. In August, HudsonAlpha announced a public-private partnership with the city of Dothan to create HudsonAlpha Wiregrass to advance education, agricultural research, and economic development through entrepreneurship. Meanwhile, the HudsonAlpha Center for Plant Science and Sustainable Agriculture recently opened a lab and greenhouse in Huntsville to grow research plants to improve existing crops and develop new uses for plants. The facility is equipped with two lab spaces, seven grow rooms with 15-foot ceilings, and several technologically advanced features rarely found in greenhouses. In addition, the HudsonAlpha AgTech Investment Accelerator opened to support startups and enhance the institute’s commercialization pipeline for new ideas. The initiative is a collaboration with gener8tor, a leading national tech accelerator. The HudsonAlpha AgTech Investment Accelerator is supported by the Growing Alabama Credit program through the Alabama Department of Commerce. “We’re committed to supporting innovation throughout Alabama’s economy, and the HudsonAlpha AgTech Investment Accelerator will be an important resource in helping us achieve that goal in this critically important sector,” Canfield said. Republished with the permission of The Alabama NewsCenter. This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

Kay Ivey announces surging 2021 exports, surpassing pre-pandemic levels

Today, Gov. Kay Ivey announced that Alabama’s exports in 2021 surged more than 20% in value compared to the previous year. This means exports have surpassed pre-pandemic levels. New federal government figures show that Alabama’s exports of goods and services totaled nearly $20.9 billion last year, above the 2019 total of $20.8 billion. 2021 exports increased more than 21.8% from the 2020 total. Many key export categories showed robust growth last year. “We are very pleased to see that our optimism at this time a year ago was well-founded. Alabama’s export numbers in 2021 exceeded those of 2019,” stated Ivey. “This is a promising sign that demand for Alabama-made goods and services remains strong and that Alabama has an integral role to play in the worldwide recovery.” Ivey stated on Twitter, “I’m very pleased to announce Alabama’s exports in 2021 surged more than 20% in value compared to the previous year, surpassing pre-pandemic levels and indicating the underlying resilience of the state’s economy.” Alabama businesses exported to 189 countries in 2021, with the top five destinations being Germany, Canada, China, Mexico, and South Korea. Rounding out the 10 top destinations for exports were Japan, Belgium, the United Kingdom, Australia, and Brazil. Transportation equipment, the state’s No.1 export, jumped 25.8% to reach $10.35 billion, beating the total for 2019. Overseas shipments of Alabama-made motor vehicles rose by 38.4%, while exports of ships and boats jumped 40% last year. “It is critical that we build on the successes of 2021 in order to keep the momentum going,” said Greg Canfield, Secretary of the Alabama Department of Commerce. “The impressive growth in exports of motor vehicles, iron and steel products, in addition to machinery, plastics, and forestry products shows that Alabama is well-positioned to meet the demands of overseas buyers in a wide variety of sectors.” Alabama ranked No. 24 among the states in export volume for 2021, moving up from No. 25 in 2020.

Aerospace, automotive summits heading to Birmingham this week

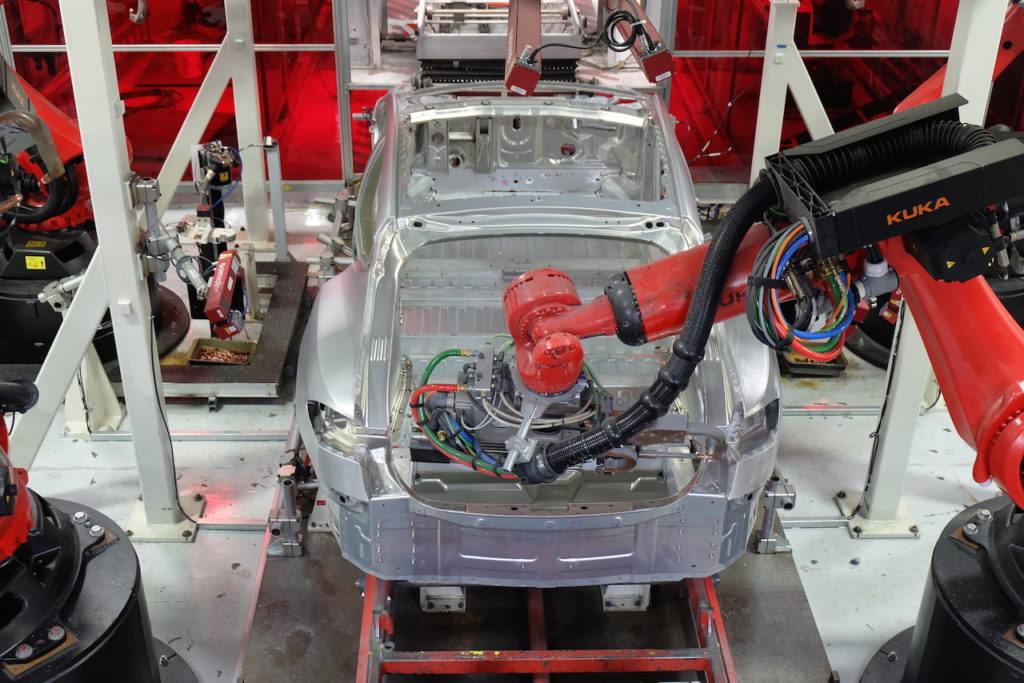

Birmingham is hosting a pair of business summits this week that showcase Alabama’s growing automotive and manufacturing industries, providing participants with high-level networking opportunities and one-on-one meetings. The conferences are the Aerospace Innovative Technology Summit (AITS), held May 7-9, and the Automotive Advanced Technology Summit (AATS), held May 8-9. Both events are taking place at the Birmingham-Jefferson Convention Complex, with 200 companies expected to participate. The Alabama Department of Commerce is among the sponsors of the summits, which feature workshops, presentations and business-to-business meetings. “The automotive and aerospace industries are major drivers of economic growth in Alabama, and these business conventions in Birmingham offer a pathway for companies from across the country and around the world to seek new opportunities and understand how their peers are utilizing and advancing the latest technologies,” said Greg Canfield, secretary of the Alabama Department of Commerce. “Besides companies from Alabama and multiple U.S. states, an international presence representing 11 different countries is here to participate,” he said. “These summits bring a focus on innovation, which is critical to growing and sustaining these manufacturing sectors and placing Alabama in a leading role for the latest technologies.” Focusing on innovation The Aerospace Innovative Technology Summit targets the aerospace, space and defense industries, all with a significant presence in Alabama. With a focus on new technologies being deployed in the sector such as 3D metal printing, digitalization of manufacturing and cyber security, the event aims to connect leading companies and participants in the sharing of ideas in the application and development of these innovations in their businesses. To kick off the aerospace conference, Canfield will provide an overview of the industry sector in the state. Other scheduled speakers include R.G. “Corky” Clinton Jr. of NASA’s Marshall Space Flight Center, Nick Bowman of GKN Aerospace and Jeff Chang of Lockheed Martin. The Automotive Advanced Technology Summit will focus on advanced manufacturing and new technologies at use within an industry growing rapidly in Alabama. Scheduled speakers include Mark Brazeal of Mazda Toyota Manufacturing USA, Tom Shoupe of Honda of America Manufacturing, and Brad Newman of ZF Chassis Systems in Tuscaloosa. Also speaking is Chuck Ernst, a former Honda Alabama executive who now serves as manager of the Alabama Robotics Technology Park, a unique training facility in Decatur. “It is an honor to have Birmingham chosen as the site for both of these conventions,” said Brian Jennings, vice president of economic development for the Birmingham Business Alliance (BBA). “It speaks to Alabama’s prominence in both the aerospace and automotive industries, and we look forward to bringing so many people together to foster continued growth of both industries.” Joining the BBA and the Department of Commerce in supporting the business conferences are the City of Birmingham, Jefferson County, the Birmingham Airport Authority, the Alabama Automobile Manufacturers Association and the Alabama Community College System. Mayor Randall Woodfin said Birmingham is the ideal location for the events. “Now, more than ever, Birmingham is focused on bringing high-quality technology jobs to our city. The summit gives a great chance to identify innovative partners that share our commitment to the next generation of manufacturing in the aerospace and automotive industries,” Woodfin said. This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

New investment fuels aerospace job growth across Alabama

Momentum continues to build in Alabama’s aerospace industry, which is adding new investments and hundreds of jobs to produce innovative, in-demand products in communities across the state. In 2017 alone, there were announcements totaling nearly $690 million and 1,750 jobs. Those numbers increased the sector’s cumulative investment over the past seven years to almost $2.4 billion, along with 8,348 aerospace and defense jobs during the same time period. This year, there’s a hiring surge, as the plans become reality. And more jobs are on the way. At last week’s Farnborough International Airshow, defense contractor BAE Systems and Carpenter Technology Corp., a maker of premium metals and alloys used in the aerospace industry, announced expansions of their Alabama operations. Together, these projects will create more than 250 jobs in north Alabama. Meanwhile, growth plans are already in place for aerospace companies operating across the state. Airbus’ Alabama factory, for instance, is in linefor 600 new jobs, thanks to a planned second assembly line for the Bombardier C Series jetliner (renamed the A220), as well as a potential increase in the production of A320 Family aircraft. GE Aviation plans to double its 90-member Huntsville workforce in the coming year and increase to 300 when the new factory complex for silicon carbide materials reaches full production. The company is also adding workers at its Auburn facility, which mass produces a jet engine fuel nozzle using additive manufacturing, or 3-D printing technologies. Targeting growth Aerospace companies from around the world are seeing that Alabama offers plenty of advantages to help them expand their business, said Greg Canfield, secretary of the Alabama Department of Commerce. “From complex military weapons systems to innovative passenger aircraft, and many of the break-through technologies that power them all, Alabama is home to an impressive array of the industry’s leading products,” Canfield said. “How do we do it? In Alabama, we take partnerships very seriously. A company’s strategic vision and expertise, coupled with the skill and dedication of our highly trained workforce, is always a winning combination.” Canfield joined Gov. Kay Ivey and an Alabama team at Farnborough for appointments with executives of 16 aerospace companies, including Airbus, Boeing, Leonardo and GE Aviation. The talks were aimed at bringing home new investment and jobs in the aerospace sector. Aerojet Rocketdyne One of last year’s key announcements was Aerojet Rocketdyne’s $46.5 million, 800-job expansion project in Huntsville. The company is consolidating its Defense division headquarters and Rocket Shop advanced programs to the Rocket City, where it has had a presence for more than 50 years. It has also moved into a new office space at Cummings Research Park and is building a new Advanced Manufacturing Facility that will produce subassemblies and components for the AR1 rocket engine, composite cases for rocket motors, 3-D printed rocket engine components and other parts. James Ramseier, site leader for operations at the Huntsville Advanced Manufacturing Facility, said construction is about 60 percent complete and right on schedule. “We plan on opening that facility in December of 2018, and initially in 2019, we are going to go through product verification. In 2020, we will ramp up to full production,” he said. Ramseier said everyone in Huntsville, from major business groups to individual building inspectors, has been supportive and welcoming. “The culture here is, ‘Let’s all work together to help make you successful,’” he said. “It’s a pleasure working in an environment where people want you to succeed. “You don’t feel like a stranger. As soon as you move here, you’re part of the family.” Aerojet Rocketdyne’s hiring plans are moving forward as well, with support from Alabama’s top worker training agency. “AIDT is fantastic. We’re working with them every week on developing our training plans and material, and they have been outstanding to work with,” Ramseier said. Forging partnerships The company is also impressed with the ties between business and education in the community, said Bill Bigelow, chief of defense communications. “The partnerships here are very attractive to us,” he said. “We’re growing the future workforce, as we grow our presence here in Huntsville, partnering with Alabama A&M University, the University of Alabama in Huntsville and other area educational institutions, as well as the chamber of commerce and the mayor’s office.” Bigelow said the Tennessee Valley is clearly committed to bringing in the types of jobs and training programs that will grow a generational workforce. “The knowledge and the history in all things aerospace, missile-defense and industrial base operations is here, and Aerojet Rocketdyne wants to leverage that community expertise both now and well into the future,” he said. Republished with the permission of the Alabama Newscenter.

Kay Ivey leads Alabama team at 2018 Farnborough International Airshow

Gov. Kay Ivey is leading a team of Alabama economic development specialists at one of the world’s largest airshows next week, for meetings aimed at accelerating growth in the state’s aerospace and aviation industry. The 2018 Farnborough International Airshow, which begins Monday, July 16 in London, is the global aerospace industry’s premier trade event in 2018. There, Ivey, Commerce Secretary Greg Canfield and a small working team from the Alabama Department of Commerce will attend appointments with high-ranking executives and key decision-makers from major aerospace companies. “In the past year, we’ve seen many exciting aerospace projects come to Alabama, and our goal is to make sure we land more of them. At the Farnborough Airshow, I will work with my team at the Alabama Department of Commerce, led by Secretary Greg Canfield, to position the state for additional growth and job creation in the aerospace industry,” Ivey said. “Alabama is a leader in aerospace, and we’re aiming to elevate the state’s profile in this important industry through even more growth.” Organizers say Farnborough will host more than 1,500 exhibitors and up to 100,000 visitors during the event’s trade show portion, which is dedicated to industry representatives and other professionals. Alabama’s aerospace Growth The air show mission comes at a time of robust growth for Alabama’s aerospace industry. In 2017, aerospace companies finalized plans for nearly $700 million in new capital investment in Alabama, which will create 1,750 jobs, according to projections by the Alabama Department of Commerce. Investment in the sector totals around $2.4 billion since 2011, resulting in 8,300 new jobs. Hiring trends within the sector remain strong, with companies including Boeing, Airbus, GE Aviation, Aerojet Rocketdyne and Blue Origin expanding their workforces in the state. Canfield said the Farnborough Airshow represents a unique opportunity for his team to engage in a series of scheduled appointments with key industry figures over three days. “At Farnborough, we can showcase Alabama’s many advantages and capabilities in the aerospace sector while positioning the state for additional investment and job creation,” he said. “Our team can connect with companies from around the world at one location, without having to travel all over the globe.” Alabama officials have attended the Farnborough International Airshow and its sibling, the Paris Air Show, for a number of years because having a presence at the industry’s most important annual events is seen as critical to efforts to land new aerospace jobs and investment. At the Paris Air Show in 2017, Ivey and Canfield attended 22 appointments with industry executives. The discussions touched on five ongoing projects and uncovered four potential new projects for Alabama. Altogether, these projects involved between 1,600 and 1,900 possible new jobs. “Alabama’s aerospace industry is thriving and gaining momentum for even more future growth,” Ivey added. “I want to see this industry continue to expand across Alabama, bringing good jobs, additional investment and new capabilities.” Ivey is the former chair of the Aerospace States Association, a nationwide group representing states’ interests in federal aerospace and aviation policy development. She is a member of the National Space Council’s Users Advisory Group.

DC BLOX building ‘flagship’ data center in Birmingham

Atlanta-based DC BLOX said today it is building a data center on the former Trinity Steel site in downtown Birmingham, creating 20 jobs initially with the potential to grow up to $785 million in capital investment and add jobs over the next decade. “The significant investment being made by DC BLOX to open this data center in Birmingham will not only create high-paying jobs, but also bring an exciting new chapter to a neighborhood in the city with a long industrial history,” Alabama Gov. Kay Ivey said. “We’re committed to positioning Alabama for a technology-focused future and look forward to working with the company to accelerate that process.” The 31,000-square-foot first phase of the multi-tenant Birmingham data center joins others DC BLOX has built or announced in Huntsville, Atlanta and Chattanooga. DC BLOX plans to break ground in August and have a facility configurable up to 5 megawatts (MW) of customer capacity by early 2019. As customers are added, the facility can grow up to 200,000 square feet and 80 MW. Plans are for the facility to have 13,000 square feet of office space with conference rooms, staging areas and work stations. “The Birmingham data center campus will unquestionably be our flagship property, capable of scaling to over 200,000 square feet of secure, government-grade data center space,” said DC BLOX CEO Jeff Uphues. “We believe this site will be a highly compelling alternative in the Southeast to Atlanta for enterprise, hyperscale cloud, software-as-a-service, government, network and content providers. It’s our focus to create a multi-purpose innovation campus with collaborative workspaces worthy of housing global technology companies and academia dedicated to research and collaboration.” DC BLOX has been scouting sites in Birmingham for nearly a year. “DC BLOX wanted to be in Birmingham because of its strong local economy, geographic location, fiber optic network connectivity and the University of Alabama at Birmingham,” said Mark Masi, COO of DC BLOX. “We are thankful to the city of Birmingham, Jefferson County and the state of Alabama for collaborating with DC BLOX on this project.” During the construction and operational phase, the project is expected to have an economic impact of $94 million on the Birmingham metropolitan area, more than $80 million of which will be in Jefferson County, according to an analysis prepared by the Center for Business and Economic Research at the Culverhouse College of Business at the University of Alabama. The Birmingham Business Alliance commissioned the analysis. Economic impact on the state is estimated to be $99 million. “Because data centers represent the backbone of the technology infrastructure, we see strategic benefits for Alabama to host state-of-the-art centers that keep the world connected,” said Alabama Commerce Secretary Greg Canfield. “DC BLOX is joining an impressive roster of technology companies selecting Alabama for their data centers, and we want to see that list grow.” Jefferson County Commissioner David Carrington predicted DC BLOX’s data center will attract future business. “DC BLOX will be a tremendous asset to the existing companies throughout Jefferson County and a tool to attract new companies here,” Carrington said. “This takes Birmingham’s thriving innovation ecosystem beyond its usual physical boundaries of the city center and extends it into an area that will only strengthen our core.” The new DC BLOX data center brings new life to the former Trinity Steel property, which county and city officials have long sought to bring back to productive use. “The city of Birmingham was proud to work with DC BLOX to bring this significant data center project to Birmingham,” said Mayor Randall Woodfin. “In addition to utilizing a long-vacant property in our city and transforming the surrounding neighborhood, this will serve as the company’s flagship data center and a tool to attract further business to the area.” The team luring DC BLOX to the site included the Alabama Department of Commerce, Jefferson County Commission, Jefferson County Economic and Industrial Development Authority, the city of Birmingham and its Department of Innovation and Economic Opportunity, Titusville Neighborhood Association, Birmingham Industrial Development Board, Alabama Power, Spire, Economic Development Partnership of Alabama and the Birmingham Business Alliance. “The $785 million investment over the next 10 years to build this data center technology campus represents the single largest project investment in Jefferson County in many years,” said Lee Smith, East Region CEO for BBVA Compass and 2018 chairman of the Birmingham Business Alliance. “DC BLOX recognizes the importance of Birmingham’s innovation and technology economy, and they share our vision that having a location near downtown will optimize the company’s growth opportunities. As with any successful economic development project, a great team worked together with the company to ensure its needs are met and that the project is mutually beneficial to the company, community and state.” Republished with the permission of the Alabama Newscenter.

Alabama officials welcome Airbus-Bombardier partnership plan

Alabama officials today congratulated Airbus and Bombardier on making significant progress toward the completion of a partnership deal that could see the companies establish a new assembly line for Bombardier’s C Series passenger jets at Airbus’ Mobile facility. Aerospace giant Airbus and Canadian aircraft maker Bombardier this morning said they have received all necessary regulatory approvals for a transaction that will give Airbus majority ownership in the C Series partnership. The deal is expected to close July 1. In the announcement, the companies said increased demand for C Series aircraft is expected to support the creation of a second assembly line at the Airbus facility in Mobile. That echoes earlier statements from company executives about plans for a possible new Alabama assembly line. Gov. Kay Ivey said Alabama is ready to support the plans to expand aircraft production at Airbus’ manufacturing center in Mobile. “The alliance between these two great aircraft manufacturers and the future production of C Series passenger jets in Mobile underscore the strength of Alabama’s aerospace industry and our skilled workforce,” Ivey said. “Alabamians take pride in their work, and we look forward to adding the C Series aircraft to the world-class products that are made with care in Sweet Home Alabama.” Accelerating growth Greg Canfield, secretary of the Alabama Department of Commerce, said the completion of the C Series partnership has the potential to turn Mobile into a major global production center for aircraft. “These plans represent a powerful testament to the partnership between Airbus and its U.S. industrial home in Alabama,” Canfield added. “This development is a win-win for Airbus and Bombardier, and it will accelerate growth in Alabama’s high-flying aerospace sector.” Airbus launched production of A320 family aircraft at the Mobile manufacturing facility in 2015. The $600 million complex now produces four aircraft a month and employs more than 400 people. “All of us at Airbus are excited to welcome the employees of the C Series Aircraft Limited Partnership into the extended Airbus team, and to welcome the C Series aircraft to Airbus’ product offerings beginning July 1. It will also be exciting to see us grow further in Mobile,” said Kristi Tucker, spokesperson for Airbus. Officials at the Mobile Area Chamber of Commerce cheered the news. “Additional capacity has always been a goal of our economic development team,” said David Rodgers, vice president of economic development for the Mobile Area Chamber. “Since the initial Airbus FAL (final assembly line) opened in 2015, more than 20 aerospace companies have located to Mobile. We’re looking forward to continuing to see additional investment here, as we work to grow our aerospace cluster.” The Airbus-Bombardier alliance was originally announced in October 2017. Republished with the permission of the Alabama Newscenter.

Hyundai to invest $388 million to prep Alabama plant for next-generation engines

Gov. Kay Ivey joined Hyundai Motor Manufacturing Alabama LLC President and CEO Dong Ryeol Choi today to announce that Hyundai is investing $388 million to construct a plant dedicated to manufacturing engine heads and enhance existing operations to support production of new models of Sonata and Elantra sedans. The investment will create 50 new jobs at the automaker’s Montgomery manufacturing complex. Hyundai Motor Manufacturing Alabama (HMMA) is preparing for the next-generation Theta III engine, which requires new technologies and components as a part of its assembly process. Nearly all of the capital investment will be spent on equipment for the engine head machining plant, including updating technology. “Hyundai is an important member of Alabama’s dynamic auto industry, and this expansion at its Montgomery manufacturing facility will power the global automaker’s drive for future growth in the U.S.,” Ivey said. “Hyundai’s significant new investment is a strong testament to the company’s confidence in its Alabama operation and in its highly skilled workforce.” Track record “With our latest expansion, HMMA continues to show its strong commitment to the people of Montgomery and the people of Alabama,” Hyundai President and CEO Dong Ryeol Choi said at today’s announcement. “Hyundai is continuing its track record of investing in new manufacturing technologies to ensure the long-term success of our only U.S. assembly plant,” he added. Hyundai said it will cost approximately $40 million to construct the 260,000-square-foot building that will house the head machining equipment. Construction on the engine head machining plant is scheduled for completion in November. The project will free up space to expand engine assembly lines in HMMA’s two existing engine plants. HMMA will begin producing the Theta III engine in April 2019 for Sonata sedans and Santa Fe crossover utility vehicles. HMMA will continue to build the 2.0 liter Nu engine for Elantra sedans at its manufacturing facility in Montgomery. The engine plants produce approximately 700,000 engines per year to support vehicle production at both HMMA and Kia Motors Manufacturing Georgia in West Point, Georgia. In March 2017, HMMA marked the production of its 5 millionth Alabama-made engine. “Over the past 13 years, Hyundai’s Alabama assembly plant has solidified a reputation as one of the industry’s most innovative and productive manufacturing centers,” said Greg Canfield, secretary of the Alabama Department of Commerce. “Hyundai’s investment to prepare the Montgomery facility for next-generation engines underscores the strength of the alliance we have formed with the automaker and sets the stage for continued growth in this mutually beneficial relationship.” Longstanding partnership HMMA, which started vehicle production in May 2005, is the River Region’s largest private manufacturer with 2,700 full-time and 500 part-time employees. “We are so very honored that Hyundai has once again chosen to significantly invest in Hyundai Motor Manufacturing Alabama,” said Judge Charles Price, 2018 chairman of the Montgomery Area Chamber of Commerce. “As home to Hyundai’s only North American manufacturing facility, the Montgomery community pledges to continue our enormously successful 16-year partnership for this new expansion and beyond.” Hyundai has made a series of large investments to expand operations at the Montgomery facility since 2000, when the plant was first announced. In 2007, the automaker added 522 jobs with a $270 million investment at the factory, and in 2011, it created 214 jobs with a $173 million project, according to Alabama Department of Commerce records. It re-launched Santa Fe production with a $52 million project in 2016. Republished with the permission of the Alabama Newscenter.

State Commerce Department wins President’s ‘E’ Award for supporting Alabama exports

U.S. Secretary of Commerce Wilbur Ross today presented the Alabama Department of Commerce with the President’s “E” Award for Export Service, the highest recognition an organization can receive for contributing to the expansion of U.S. exports. At a ceremony in the nation’s capital, Ross said the Alabama Department of Commerce has demonstrated a sustained commitment to increasing exports. “The ‘E’ Awards Committee was very impressed with the department’s formation of the Export Alabama Alliance,” he noted. “The department’s contributions to the export growth of Alabama companies through international trade missions were also particularly notable. “The Alabama Department of Commerce’s achievements have undoubtedly contributed to national export efforts that support the U.S. economy and create American jobs,” he added. Alabama companies exported a record $21.7 billion in goods and services during 2017, led by shipments of motor vehicles, chemicals, primary metals, minerals, aircraft components and paper products to 189 foreign countries. Alabama’s exports have surged 21 percent since 2011 and 50 percent over a decade, reflecting a long-term growth trend. “We are extremely honored to receive the President’s ‘E’ Award,” Alabama Commerce Secretary Greg Canfield said. “Alabama companies are creating good-paying jobs as a result of exporting their products throughout the world, and exports of goods and services continue to be an economic engine that spurs job creation and economic investment.” Finding markets The Alabama Department of Commerce’s Office of International Trade helps businesses across the state identify and penetrate foreign markets for their homegrown products. Over many years, the office has staged a series of trade and business development missions to countries around the globe, most recently to Argentina and Ecuador in April. “The Alabama International Trade program has proven to be a tremendous resource for the state’s small and medium-sized companies,” said Hilda Lockhart, director of Commerce’s Office of International Trade. “Assisting them in finding international markets for Alabama-made products is the key to growing exports and jobs at home. “Receiving this prestigious award validates the hard work that all members of the Export Alabama Alliance have accomplished since it was formed in 2004,” she added. The Export Alabama Alliance is a seamless network of international trade agencies with the fundamental objective of helping Alabama companies expand their business internationally. Lockhart and Beau Lore, an international trade specialist in the Office of International Trade, were on hand at the U.S. Department of Commerce’s Herbert C. Hoover building on Constitution Avenue to receive the award. Supporting jobs In total, Ross honored 43 U.S. companies and organizations from across the country with the President’s “E” Award for their role in strengthening the U.S. economy by sharing American ingenuity in foreign markets. U.S. companies are nominated for the “E” Awards through the U.S. Commercial Service, part of the department’s International Trade Administration (ITA). With offices across the United States and in embassies and consulates around the world, the ITA lends its expertise at every stage of the exporting process. U.S. exports totaled $2.33 trillion in 2017, accounting for 12 percent of U.S. gross domestic product. Exports supported an estimated 10.7 million jobs nationwide in 2016, according to the most recent ITA statistics. Republished with the permission of the Alabama Newscenter.

Port of Mobile taps partners to develop $60M auto export facility

The Port of Mobile is poised to become a major hub of auto export activity, with a new facility that will allow vehicles to be driven directly onto cargo ships bound for markets around the world. Representatives of the Alabama State Port Authority and AutoMobile International Terminal, a joint venture of Terminal Zárate S.A. and SAAM Puertos S.A., signed a Memorandum of Understanding this week to develop and operate a vehicle processing roll-on/roll-off (RO/RO) facility at the Port of Mobile. The signing took place in Buenos Aires, the headquarters of Terminal Zárate S.A. and also the site of a trade mission involving Alabama business leaders. The state delegation is visiting Argentina and Ecuador this week to find new markets for Alabama products and services. The agreement is a giant step forward in supporting automotive logistics in the Americas and abroad, according to James K. Lyons, director and CEO of the Port Authority. “This agreement represents a key step in diversifying the Port Authority’s business while providing a strategic asset to regional automotive shippers,” Lyons said. Important infrastructure Automobiles have long been Alabama’s top export, topping $7.75 billion last year alone. State-made models are currently loaded onto ships at ports in other states, so the new RO/RO facility at the Port of Mobile will provide a more convenient option for state automakers. “Alabama is the No. 3 auto exporter among U.S. states, with shipments to 88 countries last year,” said Greg Canfield, secretary of the Alabama Department of Commerce. “This new facility is an important piece of infrastructure that will help our automakers maintain their competitive edge as they continue to grow.” Construction on the automotive RO/RO terminal is scheduled to start by the end of this year, with completion expected by the end of 2019. The new terminal would convert about 57 acres of a former bulk material handling facility into a state-of-the-art automotive processing and logistics terminal. The 40-foot ship draft facility is served by five Class I railroads serving all of North America and immediate, unencumbered access to two interstate systems (I-65 and I-10). The overall project represents a total investment of about $60 million. Proceeds from the Port Authority’s recently awarded $12.7 million Transportation Infrastructure Generating Economic Recovery (TIGER) grant and the $28.8 million grant from the Alabama Gulf Coast Recovery Council as authorized under the Resources and Ecosystems Sustainability, Tourism Opportunities and Revived Economy of the Gulf Coast (RESTORE) Act of 2011 would help pay the cost of the project. Ideal partners In late 2016, the Port Authority initiated a Request for Proposal process to identify a potential partner in the construction of the facility to meet the region’s growing demand for finished automobile import/export facilities in the U.S. Gulf of Mexico. The authority selected the partnership between Terminal Zárate S.A. and SAAM Puertos S.A. and began concession agreement discussions for the construction and operation of the new facility. Terminal Zárate S.A. specializes in port services; cars, containers and project cargo handling operations; storage and logistics services; warehousing; equipment rental and other activities providing value to client logistic chains, economic sectors and overseas trade. It is among the largest RO/RO terminals in the Americas, with a 9 million vehicle throughput to date. “This project is a significant component of our growth strategy, and given our strong experience as a RO/RO terminal we are convinced we will develop AutoMobile International Terminal into a world class RO/RO processing and handling facility,” said Robert Murchison, president of Terminal Zárate S.A. The other partner in the joint venture, SAAM Puertos S.A., is a subsidiary of Sociedad Matriz SAAM S.A., a Chilean multinational company that provides foreign trade services by means of port terminal operations, towage and logistics. With a network of 11 ports in six countries, SAAM Puertos S.A. is one of the major port operators in South America and partners with the world’s leading shipping companies. “We look forward to work together with Terminal Zárate and the Alabama State Port Authority and bring all our knowledge and experience to the service of the terminal, and consolidate our position in America,” said Yurik Díaz, manager of SAAM Puertos S.A. Republished with the permission of the Alabama Newscenter.

Boeing expands Alabama PAC-3 missile seeker facility

Aerospace and defense leader Boeing marked the completion of a major expansion at its Patriot Advanced Capability-3 (PAC-3) missile seeker facility in Alabama’s “Rocket City.” Boeing officials joined military leaders, Gov. Kay Ivey and local officials at a ribbon-cutting ceremony for the 28,000-square-foot facility at 499 Boeing Blvd. in Huntsville. The expansion will enhance the company’s ability to produce, upgrade and sustain the PAC-3 missile seeker program. Boeing is adding 70 employees to its Alabama workforce as part of the project. “This is a proud moment for Boeing,” Jim Chilton, a Boeing senior vice president, said at the event. Boeing’s Alabama-made seekers provide active data to the PAC-3 missile, which enables it to acquire, intercept and destroy enemy ballistic and cruise missiles as well as hostile aircraft using hit-to-kill technology. Boeing invested $45 million to expand the Huntsville PAC-3 missile seeker production line in 2011. In June 2017, the company produced its 3,000th seeker at the Alabama location. The missile seekers made in Huntsville are delivered to PAC-3 prime contractor Lockheed Martin. The PAC-3 missile system is deployed with U.S. Army and Army National Guard air defense units, and it has been purchased by several international customers. Work on the new facility in Huntsville began in June 2016. Boeing impact Since arriving in Huntsville in 1962, Boeing has played a key role in building the nation’s defense and space programs in Alabama. It has long ranked as the state’s largest aerospace company, with more than 2,700 employees at two main facilities in Huntsville. “Boeing has been doing business in Alabama for more than 50 years,” Ivey said at the event. “A long time ago, Boeing found that Alabama is a good place to do business, especially in aerospace and defense.” U.S. Rep. Mo Brooks and Huntsville Mayor Tommy Battle both said the work being done by Boeing keeps the U.S. safe and protects the lives of soldiers deployed overseas. Core business areas for Boeing in Alabama include missile and weapon systems, the Space Launch System (SLS), an aerospace design center, and a research and technology center. “Boeing’s continued growth in Alabama is a testament to the company’s strategic vision, as well as the skillful execution by its extremely talented workforce in the state,” said Greg Canfield, secretary of the Alabama Department of Commerce. “Boeing’s innovative work in Alabama is critical to our nation’s defense and space programs, and the company has helped the state build a significant presence in an industry with a solid future.” Boeing’s financial impact on Alabama has been measured at $2.3 billion annually. Republished with the permission of the Alabama News Center.